Solution for Plastic injection molds

Plastic Injection Molding is the process used to produce low—or high-volume custom plastic parts for commercial and industrial use.

The applications span a range of industries, from intricate automobile safety components to simple products like business card holders.

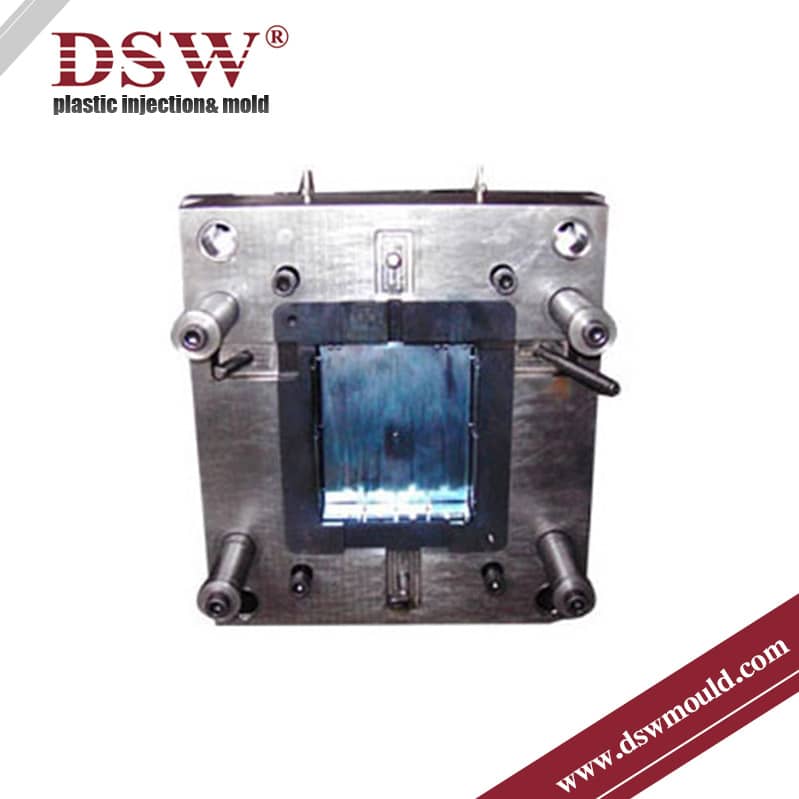

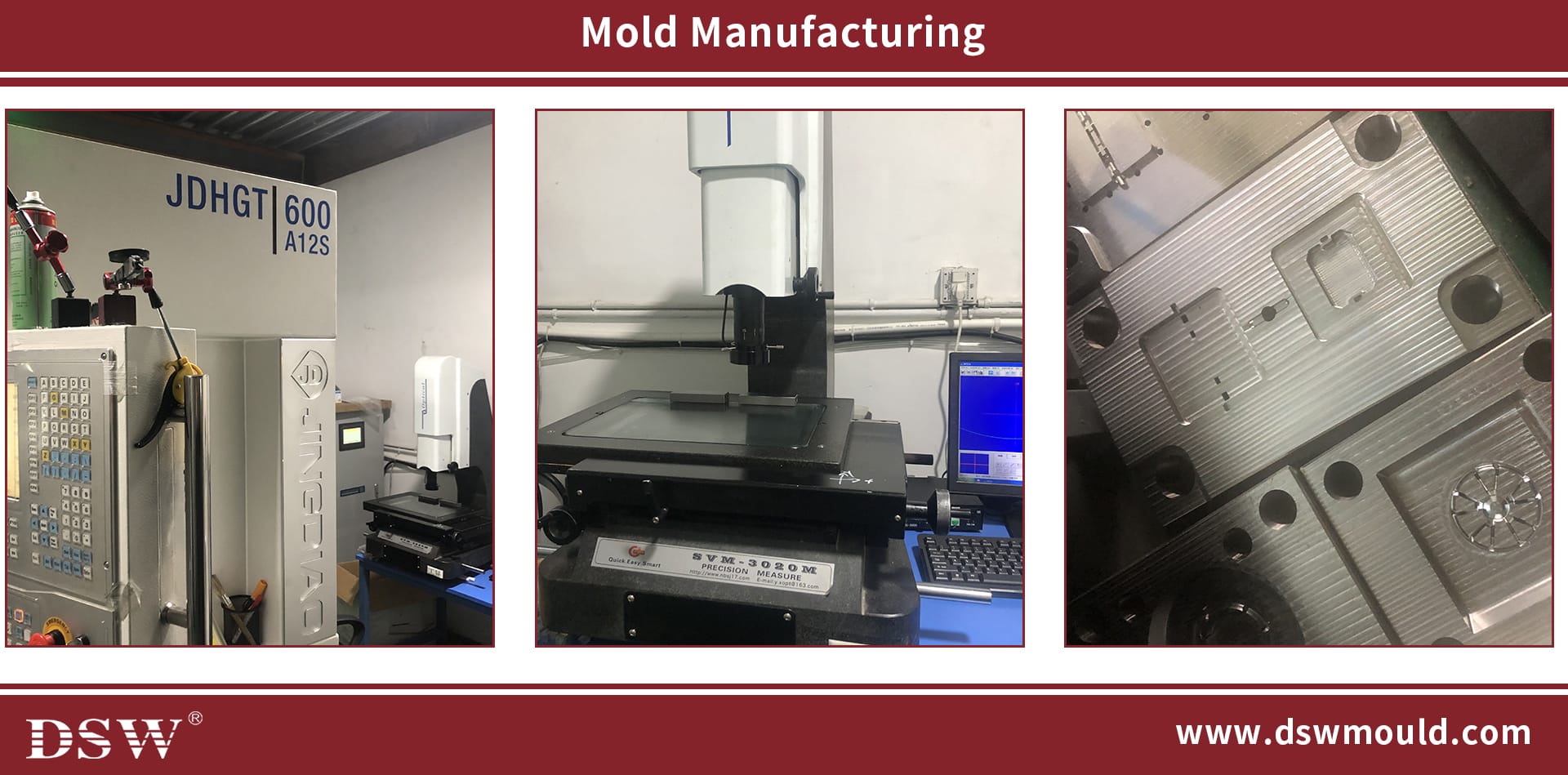

DSW uses expert mold designers, advanced software, and cutting-edge CNC machinery to create high-quality plastic injection molds.

Our team is dedicated to working with you on your mold project and ensuring the production of precise, custom-molded plastic parts.

Plastic Injection mold(British English: mould) is a manufacturing process for producing parts from thermoplastic and thermosetting plastic materials. Material is fed into a heated barrel, mixed, and forced into a mold cavity, which cools and hardens to its configuration.

| Cavity: | Custom Cavity |

| Certification: | ISO9001:2008 |

| Mould base: | LKM Mould Base |

| Product Name: | Plastic injection mold |

| Mould material: | P20/718/738/NAK80/S136 |

| Brand Name: | DSW |

| OEM/ODM: | Yes |

| Material: | Steel |

| Material Product : | Steel |

| Mould base: | LKM Mould Base |

| Mould life: | 250000-300000shots |

| Place of Origin: | Ningbo, China (Mainland) |

| Runner: | Hot Runner\ Cold Runner |

| Shaping Mode: | Plastic Injection Mould |

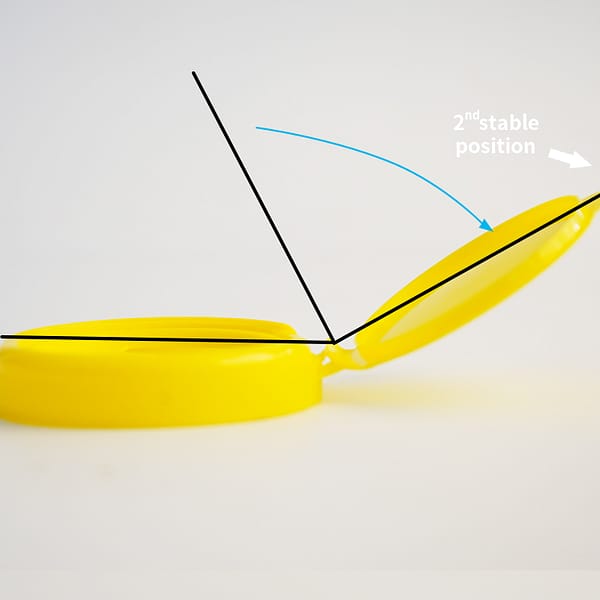

| Model Number: | PP Plastic Storage Box Lid |

| Surface treatment: | Polish. Etched. TexturePolish, Matte |

In-House Mold Builds

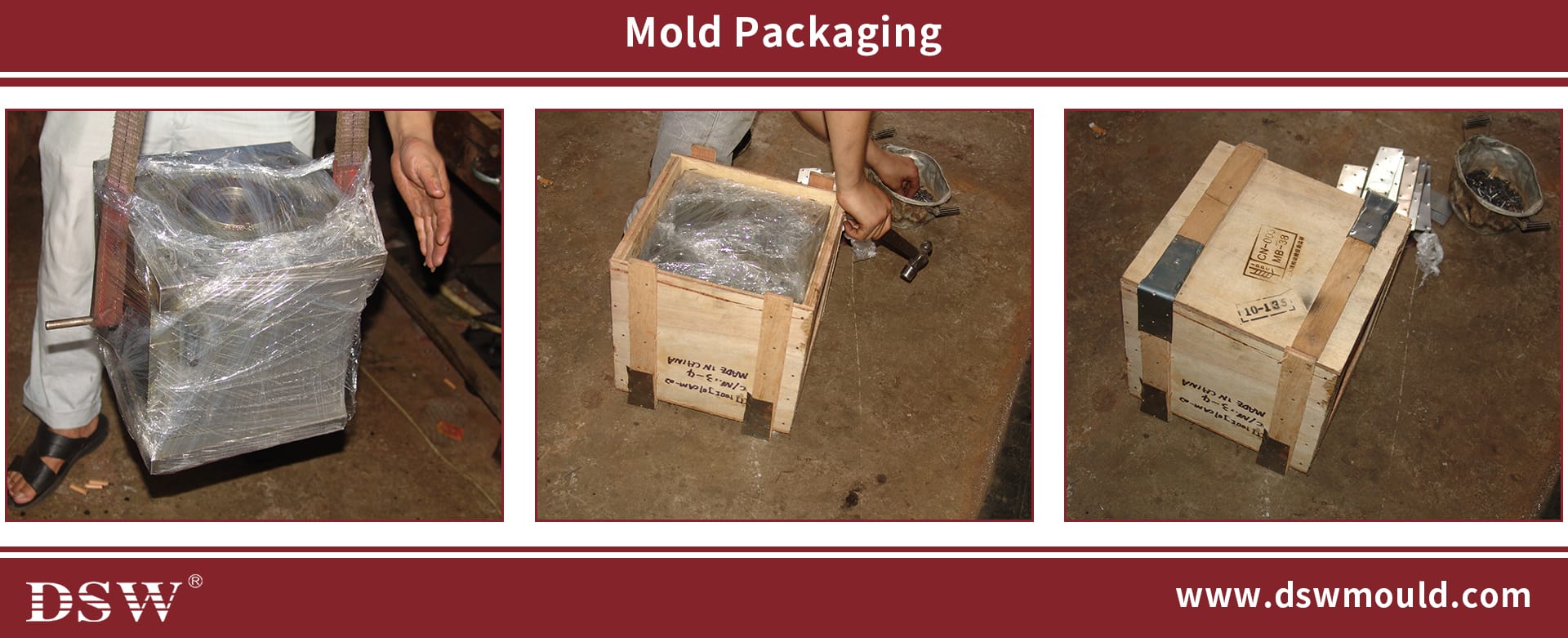

DSW builds all of its customer molds in our Ningbo factory. Our mold building area is staffed by experienced designers and machinists who use the latest software and CNC machines.

Our team will build durable, trouble-free plastic injection molds after our customer approves the finalized part design.

Molds For Plastic Injection

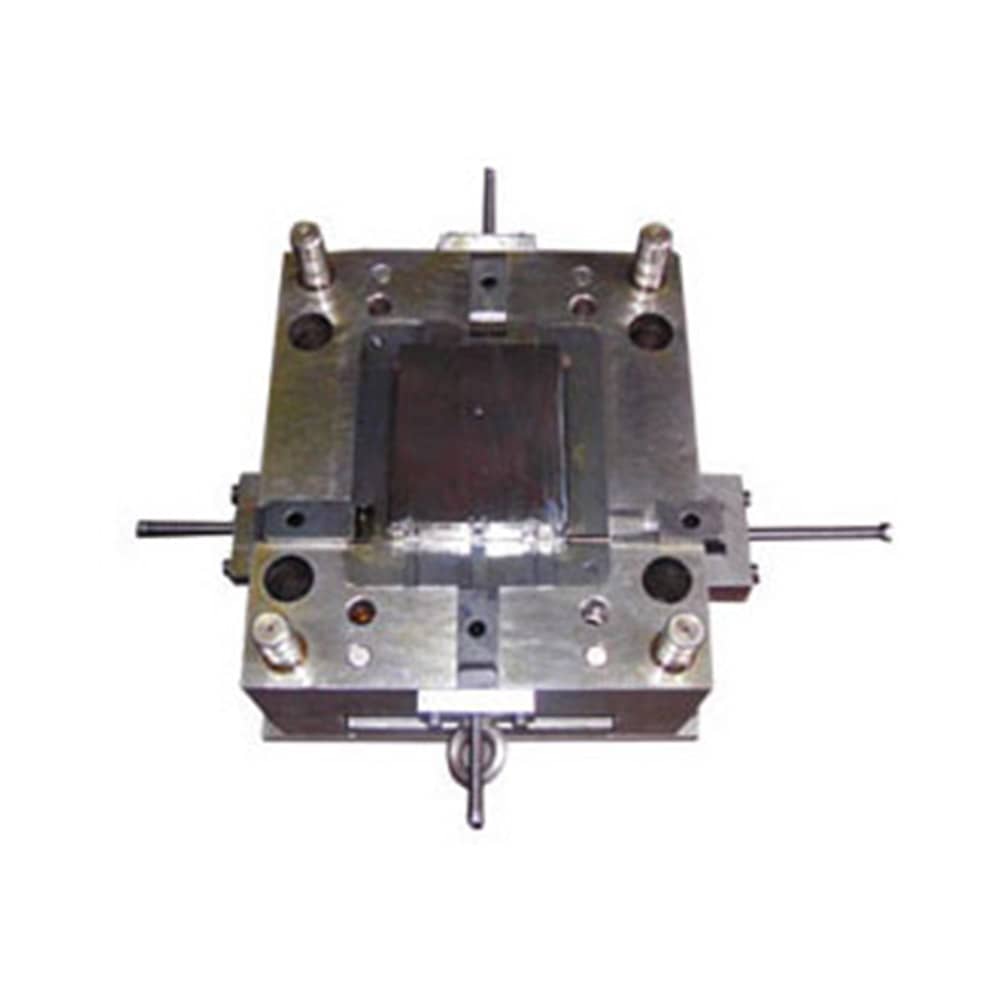

Producing high-quality plastic parts begins with having a quality-built mold. We are here to assist in creating injection molds and will work closely with you at each step. Hence, you will understand all the types available for plastic injection, their various benefits, and their construction types. Below, we present valuable knowledge regarding basic mold construction types and benefits.

Insert Moldings

Insert Molds have a cavity side and core side insert that fit inside our custom mold bases. They offer economical tooling with rapid lead times for customers requiring low-quantity orders or fast part delivery. They’re great solutions for small—to medium-sized parts that need quick turnarounds.