Plastic Automotive Molds

Precision, Reliability, and Innovation

Founded in 2004, DSW Industry is a trusted leader in the research, development, and manufacturing of plastic and automotive moulds.

We specialize in creating high-quality plastic auto mould for producing exterior automotive parts such as bumpers, grilles, engine covers, lamp housings, and more.

Our die and tooling team brings decades of experience in custom mold design, ensuring precise tooling for plastic injection and prototyping applications. We are dedicated to meeting our clients’ and their customers’ highest quality standards.

With over 20 years of expertise, DSW offers reliable, cost-effective mold solutions for various automotive parts, including plastic and metal components. Our commitment is to deliver precision-engineered molds that meet your specific needs and exceed expectations.

Benefits

Scale and Cost: They can quickly reduce the overall weight of automobile vehicles.

Material Availability: There is great flexibility in the material and colours.

Reliable: The plastic moulded car parts have high strength.

Precision Manufacturing: As a leading automotive mold maker and auto parts supplier, we produce high-precision automotive injection molds, auto part molds, and car body molds. Our commitment to precision ensures that every component meets the highest industry standards, delivering exceptional accuracy and reliability in every part.

Repeatability: Automotive moulds can consistently produce identical parts, which is crucial in the automotive industry.

Strict Quality Control: We adhere to the strictest quality control measures, ensuring that every injection-molded automotive part meets the highest standards. Each product undergoes rigorous testing by our expert team.

Superior Customer Service: Our focus on customer satisfaction ensures a smooth and professional business experience from start to finish.

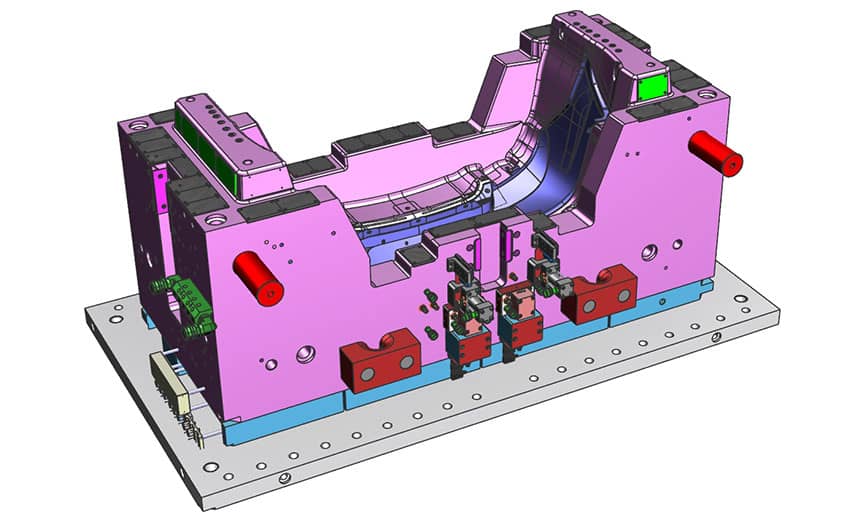

Car Bumper Mold

| Category | Details |

| Product | car bumper cover |

| Plastic Resin | PP + TD20 |

| Mold Steel | P20, 718, 2738, etc. |

| Mold Steel Hardness | HRC 28-33 |

| Runner System | Hot Runner System |

| Lead Time | 50-60 Days |

| Mold Durability | 1,000,000 Cycles |

| Cycle Time | 35 Seconds |

| Features | High-quality imported steel construction, a sequential hot runner system, an optimized cooling system, and a high-standard automotive mold for the bumper cover. |

Packaging & Delivery

| Delivery Time: | Shipped in 60 days after payment |

| Packaging Details: | Export standard carton packaging |

Advantages Of the Automotive Mould

What sets us apart in the automotive industry?

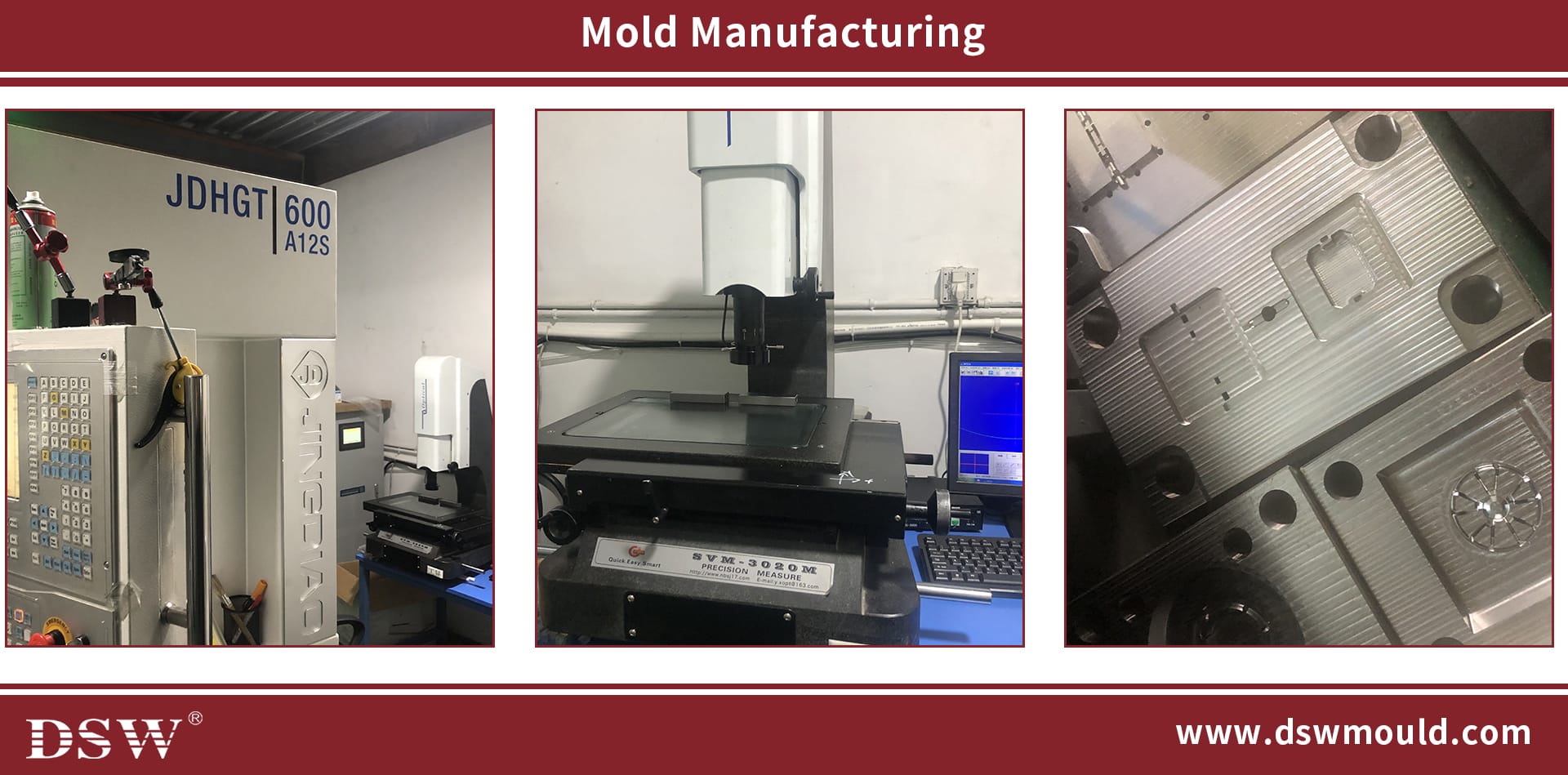

High-End Equipment At DSW, our state-of-the-art CNC machines allow us to produce large moulds with exceptional precision and efficiency, ensuring top-quality products for the automotive industry.

Technological Expertise With years of experience and a strong focus on research and development, DSW brings extensive technological expertise to every automotive project, providing innovative solutions tailored to industry demands.

Certification As an ISO9000 certified company, DSW follows the highest standards in quality management, delivering reliable and consistent products that meet the automotive industry’s stringent requirements.

Surface Treatment DSW offers a wide range of surface treatments, from premium finishes to specialized coatings, ensuring enhanced durability and performance for automotive components.

Get in Touch

At DSW, we are committed to delivering top-notch automotive mold solutions, whether it’s for car parts molds, auto parts molds, or automotive injection molds. We pride ourselves on providing precision, efficiency, and quality for all your automotive mold needs.

Contact DSW today to discuss your automotive mold needs and get a customized quote. Let us bring your designs to life with precision and efficiency.