Plastic Injection Mold Tooling

As a valued partner to the automotive industry, we supply a wide variety of high-quality plastic injection mold toolings, helping you simplify your supply chain and scale your service.

Our experienced die & tooling department personnel use their decades of combined experience in custom mold design to ensure the most precise tooling results available for injection mould tooling and prototyping applications; we meet your customers’ high-quality demands.

The basics of the injection mold tool process include creating the product design, making a tooling mold to fit the product design, melting the plastic resin pellets, and using pressure to inject the melted pellets into the mold.

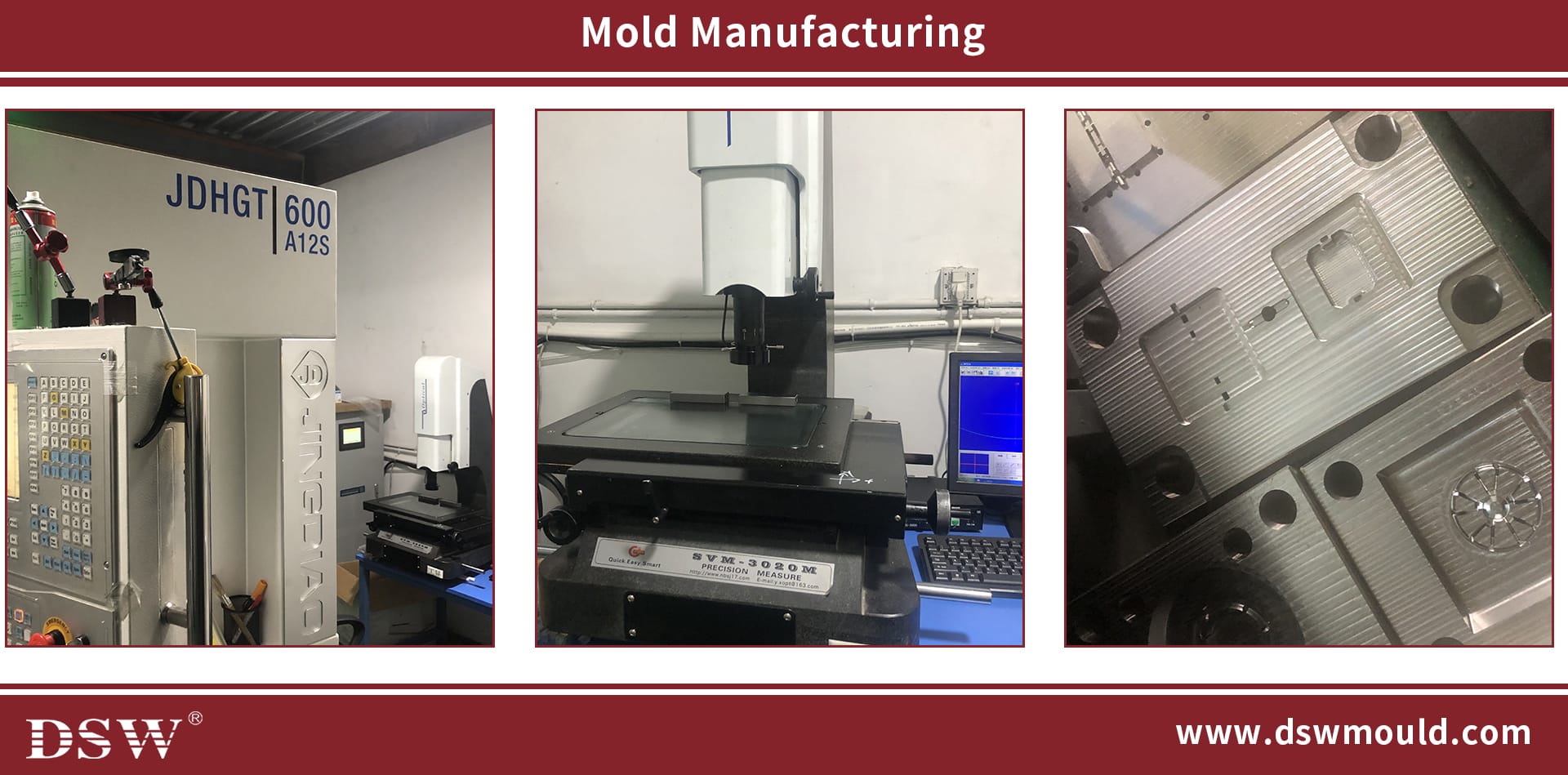

HIGH TOLERANCES AND PRECISION

Our molds are machined to close tolerances and deliver finely detailed features – no matter how intricate.

You’ll be able to produce millions of identical parts with the most incredible precision, accuracy, and consistency.

Injection Tooling

| Export to(Country) | USA |

| Tool Description | Tooling mold |

| Material Type | ABS |

| Cavitation | 1 |

| Weight of Plastic Product | 301g/pcs |

| Mould Design by | DSW |

| Mould Construction | Standard |

| Mould Base | LKM |

| Cav.Material | NAK 80 |

| Core Material | 2738 |

| Side Action | Mechanical Slide |

| Ejection | EJ pins |

| Mould Life | 500,000 |

| Moulded Part Inspection By | Moulder |

Injection Mold Tool

| Export to(Country) | USA |

| Tool Description | Injection Mold Tool |

| Material Type | ABS |

| Cavitation | 1 |

| Weight of Plastic Product | 301g/pcs |

| Mould Design by | DSW |

| Mould Construction | Standard |

| Mould Base | LKM |

| Cav.Material | NAK 80 |

| Core Material | 2738 |

| Side Action | Mechanical Slide |

| Ejection | EJ pins |

| Mould Life | 500,000 |

| Moulded Part Inspection By | Moulder |

What is injection mold tooling?

Injection mold tooling refers to the part-specific mold that produces plastic injection components.

It is made from tooling-specific grades of steel and aluminum and provides a negative cavity space into which molten plastic is injected to form a part.

Tooling has a profound impact on running components effectively and within specification.

Tooling for plastic injection molds includes sourcing and acquiring all the mold components and machinery necessary for the job.

The injection tooling consists of two parts: the mold core and the mold cavity. The space these two parts create when the mold is closed is called the part cavity.

Designing the mold and its various components represents a highly technical and complex process requiring high precision and scientific know-how to produce top-quality parts with tight dimensions.