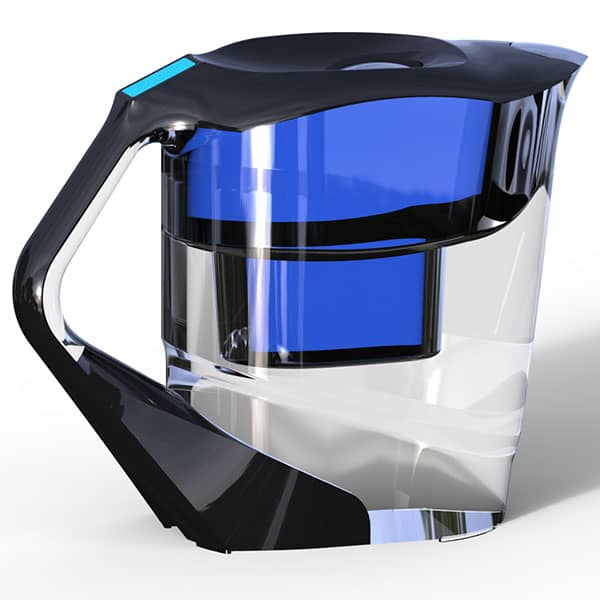

water filter jug

Stylish design, Efficiency Molds

A water filter jug, also known as a water filtration pitcher or water purifier pitcher, is a portable container designed to filter and purify tap water.

It typically consists of a pitcher or jug with a built-in filtration system that removes impurities, contaminants, and unpleasant tastes or odors from the water.

DSW is a company that manufactures water filter jugs and water purifier pitchers, offering integrated solutions from product design to mold design and final injection molding.

We have the capability to produce precision molds, ensuring that water filter jugs are made clean, beautiful, and elegant.

Advantages of water jug

Mold Design Advantages:

Precision and Consistency: High-quality mold design ensures that each part of the water jug, from the body to the lid, is produced with precise dimensions, ensuring perfect fit and function.

Optimised Material Flow: Advanced mold design techniques help optimise material flow during injection moulding, reducing defects such as warping or surface imperfections.

Ease of Assembly: Molds are designed to create parts that fit together seamlessly, simplifying assembly processes and enhancing product durability and overall quality.

Injection Moulding Advantages:

Cost-Effective Production: Injection moulding is ideal for large-scale manufacturing of water filter jugs, providing high output rates and cost efficiency with minimal material waste.

Material Versatility: This process allows for the use of various high-performance plastics, such as BPA-free materials that ensure safety and compliance with European standards.

Design Flexibility: Injection moulding supports complex shapes and intricate features, enabling innovative designs that combine form and function, such as integrated handles or textured surfaces for better grip.

Water purifier pitcher are commonly made from food-grade plastics that are safe for use with potable water. The specific type of plastic material used may vary depending on the manufacturer and product design. Some common plastic materials used in the manufacturing of water filter jugs include:

Polypropylene (PP): This is a durable and heat-resistant plastic commonly used in food containers. It is known for its high chemical resistance and low potential for leaching harmful substances into the water.

Polystyrene (PS): PS is a lightweight and rigid plastic that is often used in food packaging. It provides good clarity and is resistant to impacts.

Tritan: Tritan is a BPA-free copolyester material known for its high clarity, durability, and resistance to stains and odors. It is often used as a premium option for water filter jugs.

Acrylonitrile Butadiene Styrene (ABS): ABS is a tough and impact-resistant plastic that is commonly used in various consumer products. It provides good strength and durability.

Requst on quota

DSW supplies the plastic components needed by some of the largest manufacturers of water treatment and fluid movement equipment from all over the world.