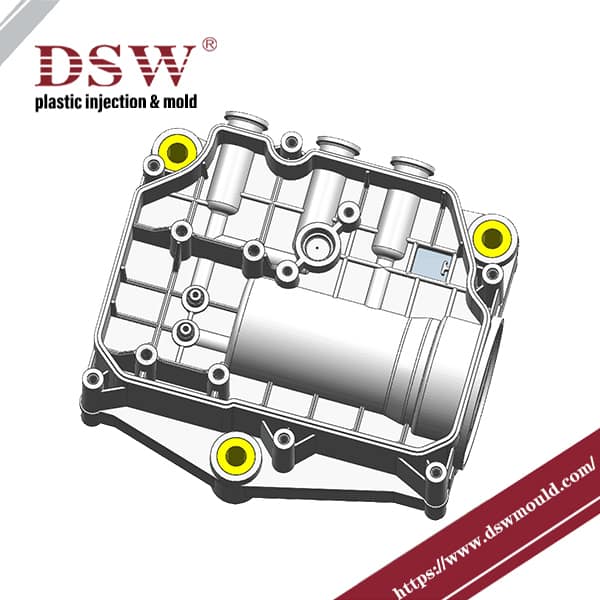

Plastic Pump Mold

Plastic pump molds are specialized molds used in the injection molding process to produce various types of plastic pump components.

These molds have specific features tailored to meet the requirements of pump manufacturing.

DSW is a manufacturing company in Ningbo City, China, with 50 years of experience in plastic pump and injection molding.

We are experts in plastic pump mould, insert molding, over-moulding, and custom injection molding.

Features of Pump Molds

Precision Mold Design: Our molds are crafted with precision to produce high-quality urea pump components with smooth finishes and tight tolerances, ensuring reliable performance in SCR systems.

Custom Solutions for Pump Manufacturing: We provide customizable urea pump mold solutions tailored to meet specific design requirements and performance standards, including options for insert molding and over-molding.

Rigorous Quality Control: Each mold is thoroughly tested and inspected to uphold DSW’s high standards, guaranteeing optimal performance for pump manufacturers worldwide.

Problem-Solving Expertise: We tackle challenges like incomplete cavity fills and air entrapment by analyzing molding process issues and offering solutions, such as optimizing die temperature, injection speed, and mold structure.

This approach ensures our molds meet exacting standards, providing durability and reliability in demanding applications.

Identifying the specific issue is essential when solving the critical problem in making a plastic pump mold.

For instance, if the mold cavity cannot be filled, it could be due to low die temperature, material temperature, injection pressure and speed, uneven plasticization of raw materials, poor exhaust, insufficient liquidity of raw materials, or premature curing of polymer melt due to unreasonable structural design.

Similarly, if air is trapped in the cavity to create bubbles in the part, it could be because the air cannot escape from the parting surface, the ram, or the vent when the two melt fronts meet.

Therefore, it is crucial to analyze the causes of the problem and propose related solutions.

The solutions could range from using more fluid materials, filling the thick wall before filling the thin wall, increasing the number of gates and runner size, reducing thickness inconsistency, ensuring uniform wall thickness, adding a vent at the last filled place, redesigning the gate and runner system, increasing injection pressure and injection speed, increasing the amount of injection, increasing material cylinder temperature and mold temperature, and more.