What is Rapid Prototyping?

Advancements in rapid prototyping and stereolithography services

Rapid modeling, also known as rapid prototyping or rapid 3D modeling, is a technique used in product development to create physical prototypes or models of a design quickly. It involves utilizing computer-aided design (CAD) software or other modeling tools to produce a virtual representation of the product, which is then fabricated using additive manufacturing technologies such as 3D printing.

DSW is proud to offer a comprehensive suite of services, including fast prototyping, stereolithography (SLA), solid free-form fabrication, selective laser sintering (SLS), and tooling and prototyping manufacturing. Our commitment to “Production in Two Weeks” ensures that our customers receive top-quality services in the shortest possible time frame, all at highly competitive prices.

Rapid Prototyping

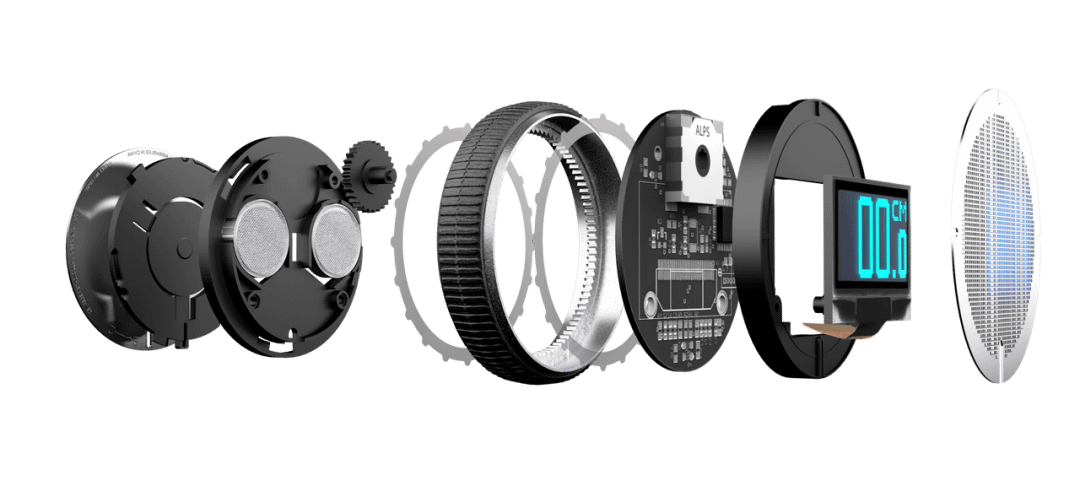

Rapid prototyping is a crucial early stage in product development, facilitating quick iterations of initial designs. Engineers and designers leverage this phase to assess the form, fit, and function of their products or components. Typically focusing on minimum viable products (MVPs), which incorporate only the essential features needed for gathering user feedback, rapid prototyping employs fast-turn or digital manufacturing processes such as 3D printing or CNC machining. These methods enable designers to swiftly test multiple iterations before finalizing a design.

Stereolithography (SLA)

SLA enables the creation of highly accurate components with intricate details. These components are valuable for rapid prototyping and proof-of-concept of interfaces, although they may become brittle over time.

Commercial Applications of Fast Prototyping

Only the creativity of designers can limit the applications of 3D printing and prototyping in design and manufacturing. From proof of concept to design optimization, RP prototyping plays a pivotal role in streamlining the manufacturing process and in various stages of product development.

What are the Advantages of Rapid Modeling??

Faster Time, Cost Efficiency, Improved Design, Testing, and Validation

- Reduction in production costs, making it cost-effective.

- Enables testing of products before the commencement of complex tooling.

- Faster Time-to-Market: Ideal for design verification, with models built within 48 hours.

- Enhanced Design Precision: By creating physical prototypes early in the design phase, designers can quickly pinpoint flaws, functional issues, or opportunities for design improvement, leading to a more refined final product. This approach reduces the likelihood of costly revisions later in the development cycle.

- Enhanced Collaboration: Rapid models allow teams to visualize and interact with prototypes early in the design process. This enhances coordination and decision-making among design, engineering, and production teams.

- Lower Risk: Rapid prototyping allows manufacturers to assess various materials and designs without committing to large-scale production. This approach reduces the financial risk associated with product development and ensures that only viable designs progress to production.

Facilities:

- Full 3D-CAD facilities ensure the translation of superior designs into high-quality finished products, guaranteeing the intended precise shape in the design.

- Precision Prototyping employs CNC machining centers that can operate up to 20,000 rpm, allowing for intricate precision etching on a micron scale. It focuses on producing carbon- and glass-reinforced plastic and etched products made from magnesium and aluminum.

- Machines utilise digital data to create models in the production process, while lasers enable accurate production. This process, facilitated through the internet, ensures fast and precise manufacturing.

- The ABS molding system aids in producing accurate models and ultra-small designs, further expanding the possibilities of prototyping.