Introduction to Mold Flow Analysis in Injection Molding

Designing high-quality injection molds is a complex task that requires meticulous planning and precision. Traditionally, the process relied heavily on the designer’s experience, often leading to extensive debugging and modifications after the initial design. This approach could result in inefficiencies and production gaps, even with experienced engineers dedicating weeks or months to ensure accuracy.

Advancements in Mold Flow Analysis Technology

The continuous improvement of professional software has significantly enhanced mold flow analysis technology. This technology allows for the preemptive analysis of mold design rationality, reducing the number of mold trials needed, accelerating product development, and boosting enterprise efficiency. High-end CAD/CAE/CAM software can significantly improve mold design efficiency and shorten manufacturing time, though it primarily addresses issues from a design perspective and may not fully resolve certain production challenges.

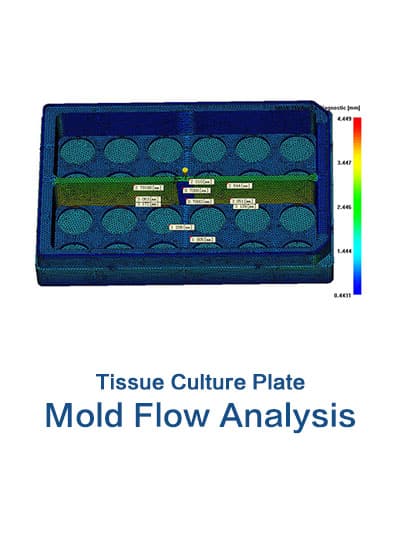

Moldflow is a professional software used to design and manufacture plastic products and molds. It simulates the entire injection molding process, evaluates and optimizes each step, and analyzes plastics before mold manufacturing. This comprehensive approach improves product design, production, and quality, assisting technicians in optimizing various critical points throughout the process.

Practical Application of Moldflow Analysis

To illustrate the practical application of Moldflow, consider the example of an injection molded part, such as a small plate. Inadequate mold design, improper material selection, or incorrect process parameters can lead to defects like warping deformation, flash, weld marks, and prolonged molding cycles.

Moldflow software enhances mold development efficiency, reduces development cycles, minimizes mold trials, and improves product qualification rates by conducting a mold flow analysis prior to mold development. Initially, the optimal gate position is determined for injection molded parts. Subsequent analyses, including filling, holding pressure, and warpage analysis, predict potential quality issues. Finally, by analyzing optimization plans, the best materials for injection molded parts are selected to enhance product quality, production efficiency, and qualification rates.

Detailed Analysis Process

Model Modeling and Pre-processing

The three-dimensional model of the injection molded part (dimensions: 140 mm × 85 mm × 3 mm, wall thickness: 1.5 mm) is created using a 3D solid mesh model. The finite element mesh is divided with a global mesh side length of 1.3 mm. A CAD mesh model with 822,409 mesh units is created, diagnosed, and repaired (average aspect ratio: 7.38).

Optimal Gate Location Analysis

The gate’s position significantly impacts the melt flow within the mold cavity, influencing polymer molecule orientation and post-molding warpage. Selecting a suitable gate position is crucial. Moldflow’s powerful analysis capabilities assess flow resistance and balance, determining the optimal gate position to ensure flow equilibrium. This rational design mitigates potential issues and enhances initial mold trial success rates, shortening product design and launch cycles, reducing production costs, and bolstering corporate competitiveness.

Analysis Sequence and Process Settings

The analysis sequence can be customized, including options like filling, holding pressure, warpage, cooling, and more. In this case, the analysis type is filling + holding + warpage, analyzing melt flow behavior, the holding stage’s impact on part quality, and warpage deformation. Default process parameters include mold surface temperature, melt temperature, injection pressure, holding pressure, holding time, and cooling time.

Results of Mold Flow Analysis

The analysis results for the small plate include:

- Filling time: 0.8694s

- Flow front temperature: 227~232.7°C

- Pressure during speed and pressure switching: 44.26 MPa

- Volume shrinkage rate: 19.68% (average: 3.103%~18%)

- Warpage deformation: 1.43 mm (warpage deformation: 10.21%)

Issues identified include significant volume shrinkage leading to severe warpage deformation. Optimization efforts should focus on reducing the volume shrinkage rate to minimize warpage deformation.

Optimization Analysis

To enhance product quality, material substitution is proposed. For example, using PS material from INEOS Styrolution (Styrolution PS 1300) can reduce volume shrinkage and warpage deformation. Moldflow optimization analysis showed:

- Volume shrinkage reduction from 19.68% to 7.588%

- Average volume shrinkage reduction from 18% to 6.173%

- Total warpage deformation reduction from 1.43 mm to 0.5787 mm

- Warpage deformation reduction from 10.21% to 4.13%

Conclusion

Moldflow technology significantly aids in designing injection molded parts by predicting quality issues and optimizing design and analysis.

This approach minimizes empirical evaluation errors, reduces development costs and cycles, and enhances overall product quality.

Quality-Assured Plastic Injection Molding Services

DSW, established in 1998, is a leading injection molding company serving global clients from China. Our advanced process controls and technologies guarantee high-quality products tailored to exact specifications, delivered punctually.