High-Precision Injection Molds for Lego-like Bricks and Parts

From toy manufacture to engineering projects, DSW offers premium injection molds for Lego-like bricks and pieces utilized in many different sectors. Our clients get the greatest plastic moulds since we are dedicated to accuracy, modern manufacturing techniques, and worldwide service. Whether your business is in the toy sector or architecture or demands custom moulds for promotional goods, we have the knowledge and tools needed to produce excellent performance moulds.

Application Scope

Our plastic molds are designed for overseas consumers that demand Lego-like components with extraordinary durability and accuracy. From toy building blocks and instructional kits to custom molds for business promotional items, these shapes find use in many different fields. We are aware that the Lego sector expects first-rate quality, particularly with relation to structural integrity and exact fitment. Your reliable friend for making Lego-like elements that satisfy aesthetic and practical criteria is DSW.

High-Precision Injection Mold Process

Material Selection

To ensure performance and lifespan, we use high-quality materials such as polycarbonate (PC) and acrylonitrile butadiene styrene (ABS) to make Lego-like bricks.

- Polycarbonate (PC) offers excellent strength and impact resistance, making it ideal for the toy industry’s transparent canopies and speciality parts. Lego-like bricks are manufactured of acrylonitrile butadiene styrene (ABS), a popular polymer known for its stiffness, flexibility, and excellent detail preservation.

Every item made from these materials meets industrial requirements because it strikes the perfect mix of cost-effectiveness, durability, and accuracy.

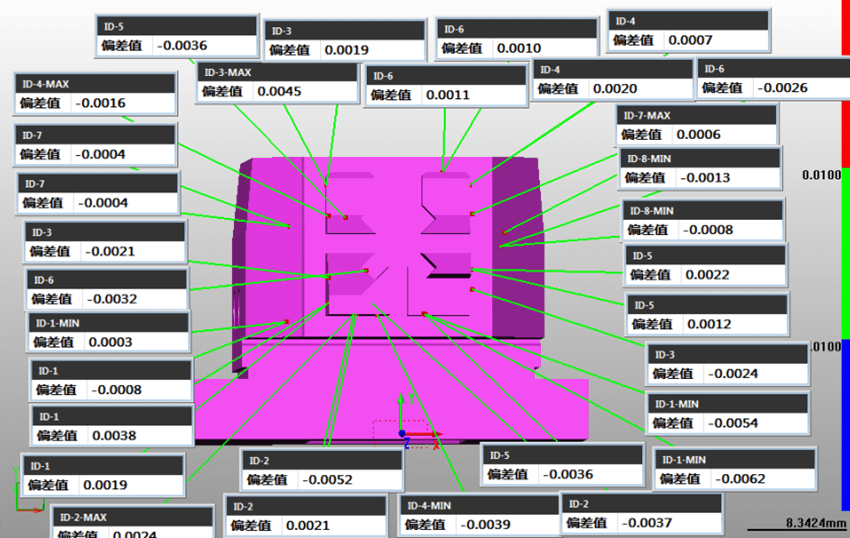

Tolerances and Mold Types

For Lego-like parts, even minor deviations can impact fit and functionality. We maintain tolerances as tight as ±0.005 mm to ensure perfect alignment. Even the slightest variation can result in poor fitting and lower product quality. The standard pulling force between two Lego bricks with two heads is 0.3-0.5 kg. The standard Lego mold tolerance is ±0.002 mm. For example, a 0.02 mm variance in size can significantly affect the tightness of the fit, and anything beyond 0.03 mm can render the item unusable.

To accommodate these tight tolerances, we employ a range of Lego mold types, including cold runner moulds and family molds. Cold runner molds are ideal for reducing waste and improving production efficiency, while family molds allow for the production of multiple parts in one cycle, increasing productivity.

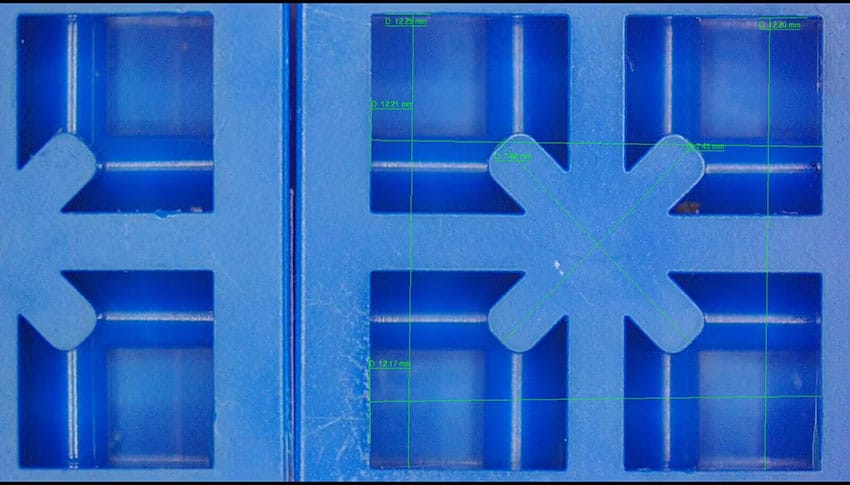

Dimension Inspection

Tools for Precision & Accuracy Measurement

We employ highly precise measuring procedures to confirm every molded component.

Electronic microscopes‚ ensure accurate interior and external sizes.

Digital Optical Microscope: Used for non-contact surface analysis and fine feature inspection.

Custom inspection tools and specific gauge pins are required for mass manufacturing because they provide greater accuracy than standard calipers.

For external dimensions, we employ callipers to verify the measurements. This dual-check system guarantees the highest level of consistency, ensuring that every molded part meets the exact specifications required for perfect fits.

Ensuring Dimensional Accuracy

High-precision Makino CNC machines allow us to create Lego-like molds with spindle speeds ranging from 20,000 to 40,000 RPM and positioning accuracy less than 1 micron.

We use top brass for EDM electrodes to improve durability and accuracy.

The manufacturing process is defined by strong quality control. Mirror EDM (electric discharge machining) produces smooth, flat surfaces and preserves strict dimensional tolerances.

This sophisticated approach reduces hand polishing, guaranteeing a consistently good finish with minimal post-processing required.

Handling Mold Defects

We are careful about possible flaws like sink marks, warping, and weld lines, even while creating moulds for Lego-like components. These flaws could compromise the parts’ appearance and structural soundness. We apply certain methods during the molding process, like mold design optimization and temperature management, to prevent these problems. This guarantees that flaws are kept to a minimum and that any that do surface fall within reasonable bounds.

Customizing for Clients from Other Countries

To satisfy international customer needs, DSW provides tailored injection moulds or Lego brick molds. Every market and customer has different needs; hence, we know whether branded parts, custom colours, or particular dimensions are necessary. Whether a minor design modification or a complete revamp, our staff works with every customer to produce molds that match their specific demands.

Our knowledge of bespoke mold creation qualifies us as a preferred partner for customers who need accuracy, adaptability, and premium output.

Quality Assurance and Global Reach

At DSW, we are committed to ensuring that every mold we produce meets the highest quality standards. Our molds undergo rigorous testing and inspection to meet international standards such as ISO and ASME. We also offer global shipping to ensure that our international clients receive their molds on time and in perfect condition. Whether in the Americas, Europe, or Asia, DSW ensures that your order is handled efficiently and professionally.

Case Studies and Successful Projects

Our expertise has been demonstrated in numerous projects for clients across different industries. For instance, we provided precision Lego-like molds for a European toy manufacturer, enabling them to produce high-quality building blocks for educational kits. By using family moulds and optimizing the injection moulding process, we helped reduce costs while maintaining tight tolerances.

Another success story involves a client in the construction industry who required customized Lego-like parts for promotional giveaways. We delivered the moulds on time, with precise internal and external dimensions, and ensured they met their branding design requirements.

At DSW, we appreciate the need of accuracy in producing Lego-like molds that satisfy the stringent criteria of sectors all around the globe. Our comprehensive inspection methods and high-precision injection moulding knowledge guarantee that your molds run faultless in large production. Whether in the toy, advertising, or architectural sectors, DSW provides the knowledge, adaptability choices, and quality control needed to create robust, Lego-like parts.

Find Better Solutions

Contact us today for a customized quote or more information on how DSW can support your injection moulding needs.