WaterMeter Mechanism

DSW is a prominent watermeter Mechanism, components, and metering solutions supplier in China.

We offer a wide range of water meter mechanisms, including positive displacement and turbine-based designs.

The water meter Enclosure is the protective casing or housing that surrounds and protects the water meter’s internal components.

Size (mm) – Refers to inside bore diameter.

Max Flow Rate (Q m3/h) – Refers to the emergency flow rate in the event of system failure. Damage may result.

Nominal Flow Rate (QN m3/h) – Typical application for everyday usage.

Transitional Flow Rate (L/hr) – The point at which the flow rate is high enough to achieve an accurate measurement.

Minimum Flow Rate (L/hr) – The absolute minimum flow required for the unit to function.

EEC Approved Class – The EEC Classification system measures accuracy at meagre flow rates.

Standard ISO4064/BS5728/EEC Specification Class B applies.

What Are the Key Plastic Components in a Water Meter?

Here’s a list of standard plastic components found in water meters:

Plastic Housing/Body: The main outer casing is typically made of durable plastic to protect internal parts and prevent water leakage.

Measuring Chamber: Encased in plastic, this chamber holds moving parts like pistons or turbines that measure water flow.

Gears: Small, precise plastic gears transfer the motion of water flow to the display or sensor, enabling accurate readings.

Impeller/Turbine: Often made of plastic in smaller or low-cost water meters, the impeller rotates with water flow to measure volume.

Register Base and Cover: The frame and protective cover for the dial or electronic display are typically moulded from transparent or translucent plastic for readability.

Sensor Housing: This plastic casing protects sensors from water and environmental exposure in electronic or smart meters.

Seals and Gaskets: Plastic or elastomer seals prevent water from entering sensitive areas, ensuring watertight integrity.

Battery Compartment: In intelligent meters, plastic housing often holds the battery, protecting it from water exposure.

Communication Module Housing: Protects the electronic components used for remote data transmission.

Flow Restrictors and Control Valves: These are sometimes included to manage or regulate water flow. They are often moulded from plastic for durability and corrosion resistance.

Using plastic for these components offers durability, resistance to corrosion, and cost efficiency, which are essential for the performance and longevity of water meters.

Key Challenges

Plastic Molding for Durable, Accurate Water Meter Components

Dimensional Accuracy: Water meter components, like gears, housings, and connectors, need high precision to ensure proper functionality and accurate readings. Achieving this level of accuracy in plastic moulding can be challenging, particularly for complex or small parts.

Material Durability: Water meter parts must withstand long-term exposure to water, pressure, and temperature changes. This requires materials that resist wear, corrosion, and deformation. Selecting the suitable plastic resin (such as nylon or POM) and the proper additives is crucial to ensure durability and longevity.

Features

Accuracy: Accuracy is a critical quality factor for water meters. The gear train translates the rotational movement from the measuring chamber into readable units showcased on the register. This intricate assembly typically encompasses gears, shafts, and other essential mechanical components. However, as time progresses, accuracy may be compromised due to mechanical wear and tear or other contributing factors, ultimately leading to imprecise water consumption measurements. Consequently, this can give rise to billing discrepancies and customer dissatisfaction. Therefore, it is imperative to ensure high accuracy by employing high-quality PC or ABS plastic parts and robust mechanical components.

Durability: Water meter mechanisms should be designed to withstand the harsh conditions often encountered in water distribution systems, including exposure to water, chemicals, and varying temperatures. Poor durability can result in premature failure, leading to the need for frequent replacements and increased maintenance costs.

Component Reliability: The reliability of individual components within the water meter mechanism is essential. Components such as gears, bearings, and sensors should be designed to withstand frequent usage and potential mechanical stress. Failure of these components can lead to meter malfunction or inaccurate readings.

Tamper Resistance: Water meters should be designed to deter tampering or unauthorized access. Any vulnerabilities in the mechanism that allow tampering can result in water theft, inaccurate readings, or damage to the meter.

Regulatory Compliance: Water meters must comply with industry standards and regulations to ensure accurate measurement and fair billing. Non-compliance can result in legal issues, disputes, and loss of customer trust.

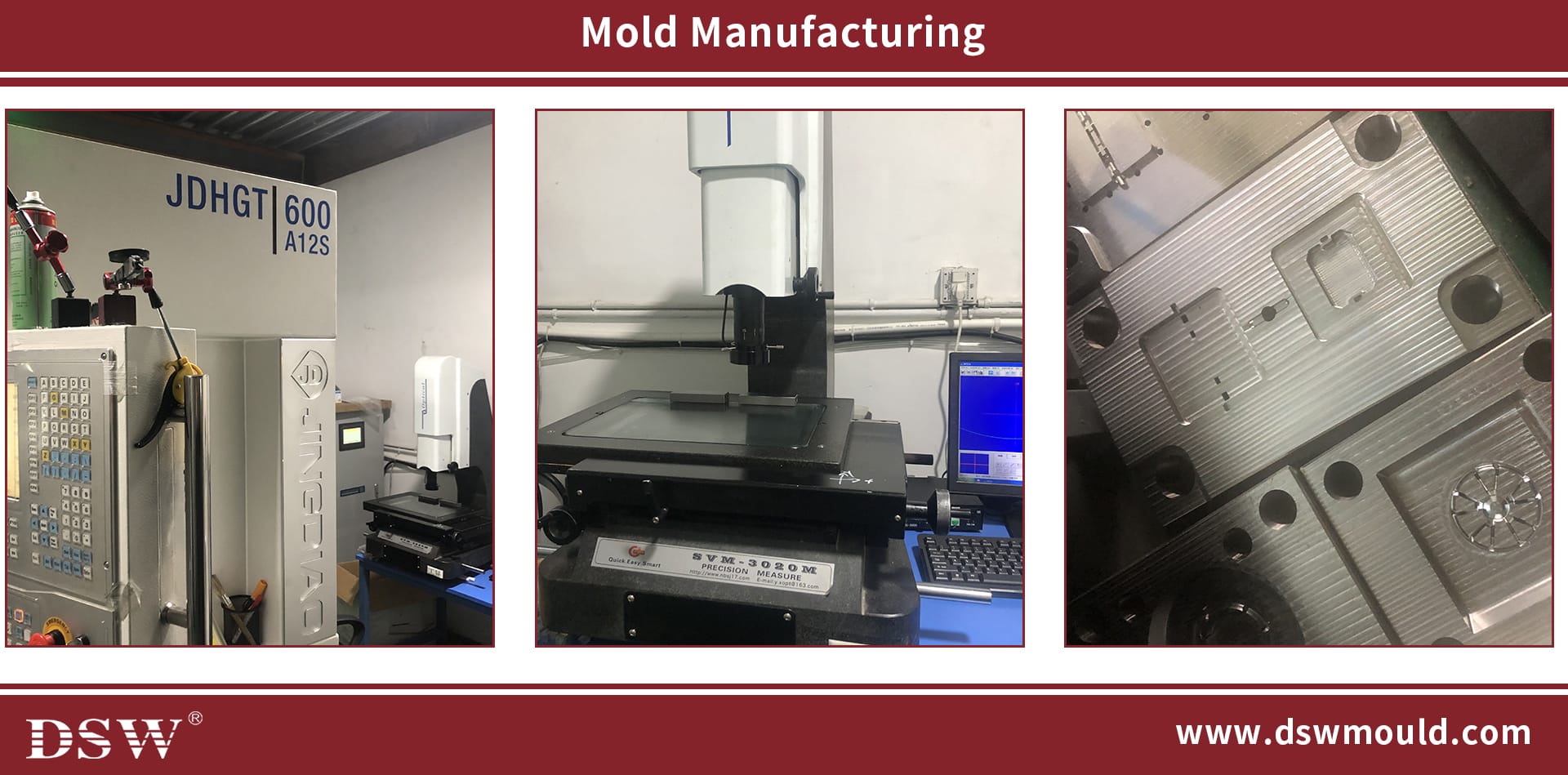

DSW provides mold designers and moulders for water meter mechanisms with improved performance and flexibility opportunities.

Extending actions beyond the mold base and pulling slide cores at complex angles can simplify design, reduce mold size and decrease cost per part.