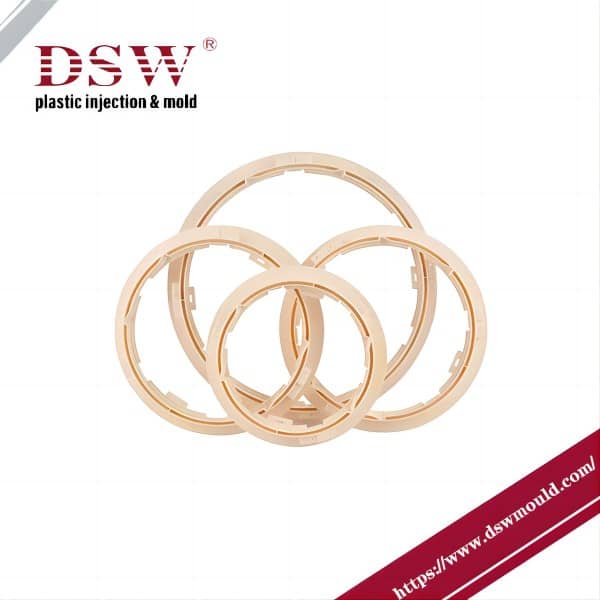

Plastic Motor Damper, Supports Hooks

An air duct damper is a mechanical device used in HVAC (Heating, Ventilation, and Air Conditioning) systems to regulate or control airflow within the ductwork.

It is designed to adjust or modulate the amount of air passing through a specific section of the duct, thereby controlling the airflow and balancing the distribution of conditioned air throughout a building or space.

DSW is a trusted supplier of plastic parts for ventilation and air conditioning systems. Our product lineup includes essential components such as plastic motor dampers, air duct dampers, diffusers, vent hood dampers, and fan blowers. With a focus on reliability, DSW is dedicated to providing high-quality products that meet the industry’s needs.

Super robust injected moulded plastic construction Supports hooks for easy hanging Holding teeth enabling the easier fitment of flexible duct core 10mm closed cell polyethene foam insulation material with consistent all-round thickness Available in six sizes Supplied with 24V or 240V cable

| Cavity: | Custom Cavity |

| Certification: | ISO9001:2008 |

| Product: | Plastic Motor Damper |

| Runner: | Hot Runner\ Cold Runner |

| Product Name: | Plastic Injection Mold |

| Mould Material: | P20/718/738/NAK80/S136 |

| Brand Name: | DSW |

| OEM/ODM: | YES |

| Material: | Steel |

| Product Material: | Steel |

| Shaping Mode: | Plastic Injection Mould |

| Mould Life: | 250000-300000shots |

| Place of Origin: | Ningbo, China (Mainland) |

| Mould Base: | LKM/ HASCO/ DME Mould Base |

| Surface Treatment: | Polish, Etched, Texture, polish, Matte |

| Runner: | Hot Runner\ Cold Runner |

| Model Number: | Damper Motor Internal 24v |

| Surface Treatment: | Polish. Etched. TexturePolish, Matte |

Packaging & Delivery

| Delivery Time: | Generally, mould-making will take around 30 days. |

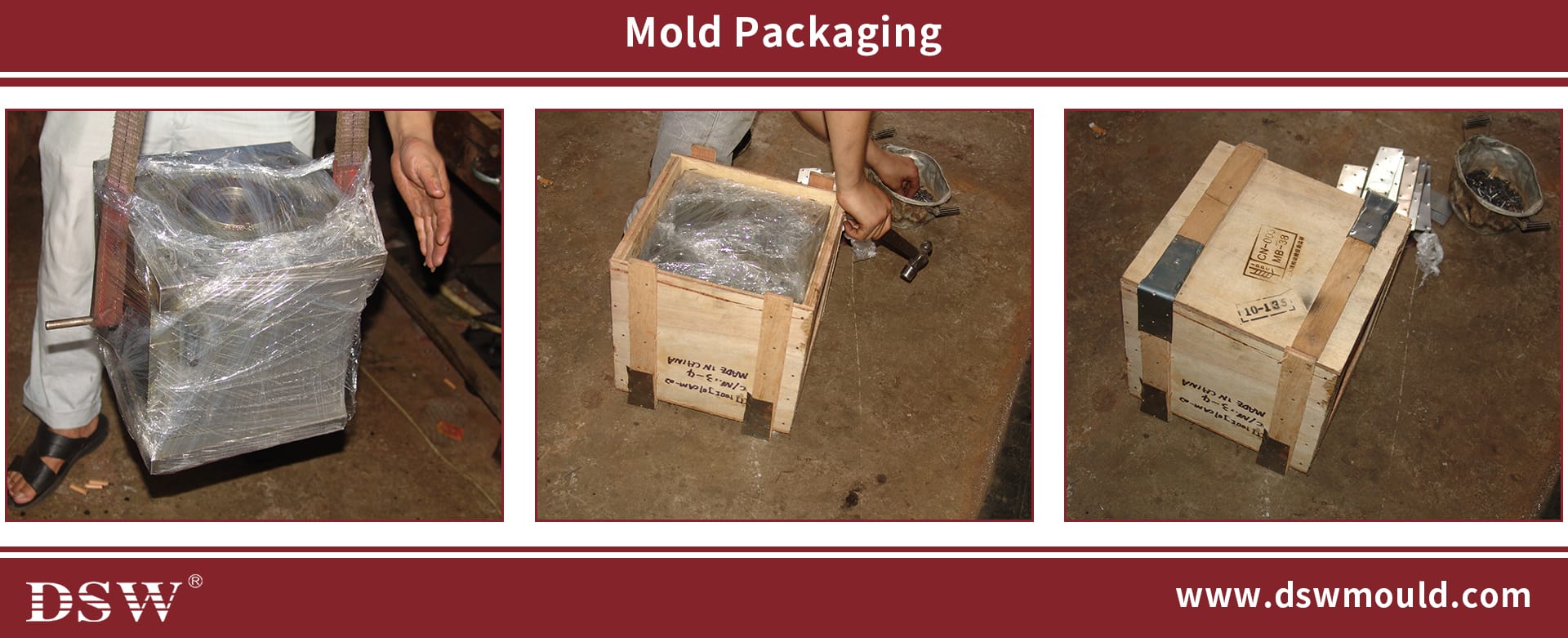

| Packaging Details: | Wooden packing boxes for moulds are generally inner packed in opp bags, outside packed in standard export cartons with shipping marks, and the cartons will be full of bubble bags. |

Product Description

| Mold Material | 45#,P20 steel, 718, 2738, H13, NAK80, 2344, 2343, S136, etc . |

| Mold Type | Plastic Injection Molding |

| Product Material | ABS, PA, PA66+GF, POM, PC, PP, PET, TPE, PVC, HDPE, etc |

| Mold Standard | HASCO, DME, MISUMI, JIS, LKM, etc. |

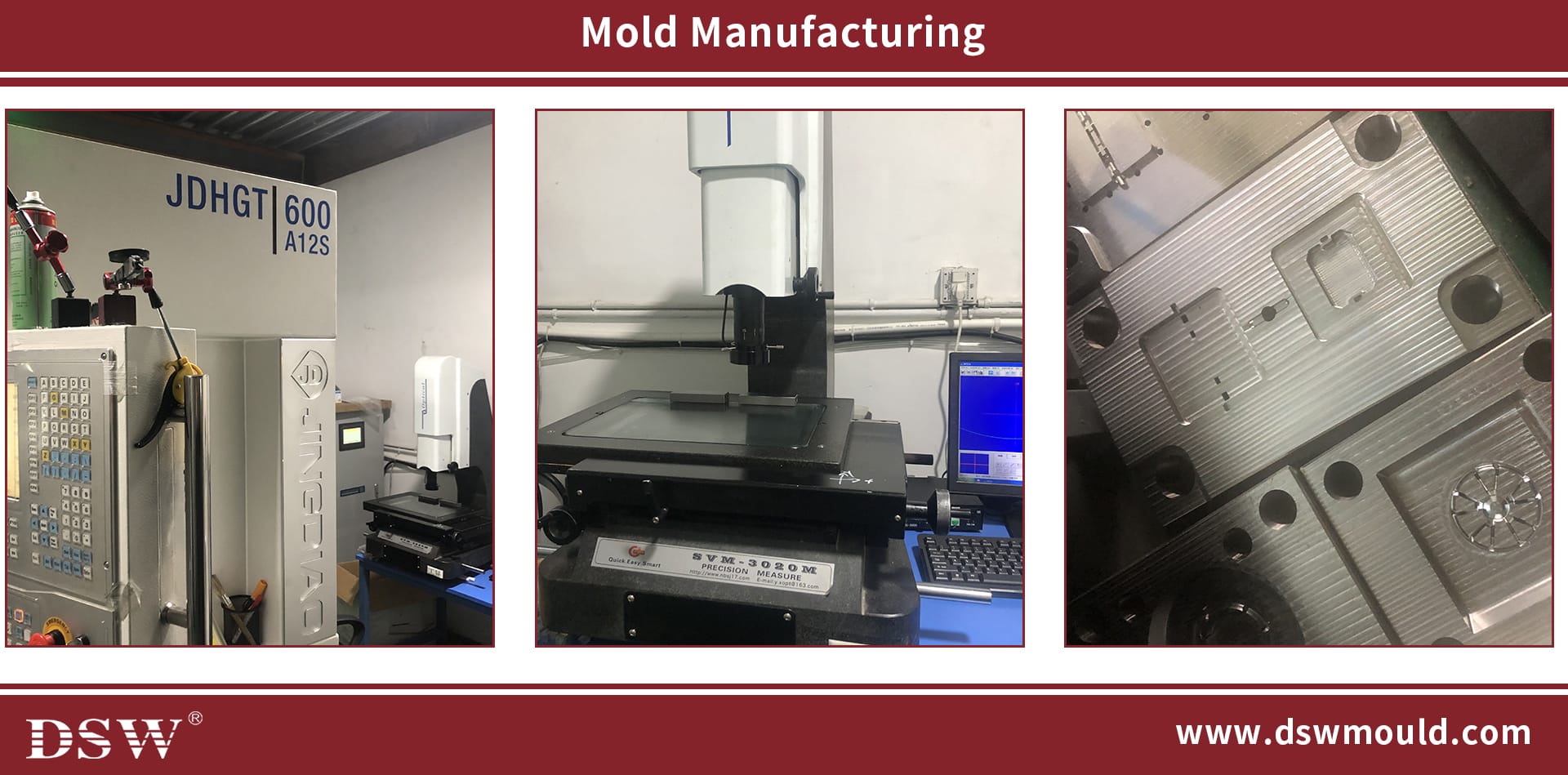

| Mold Tooling Equipment | Lathe, Milling, Grinder, Drill, CNC, EDM, Wire cut machine, Punch machine |

| Gate Type | Side Gate, Sub Gate, Direct Gate, Hook Gate, Pin Point Gate, etc. |

| Runner Type | Cold Runner or Hot Runner |

| Cavity | Single or Multi cavities |

| Mold Life | 45#:50,000 to 100,000 shots |

| P20:100,000 to 200,000 shots | |

| 718: 200,000 to 300,000 shots | |

| H13: 300,000 to 500,000 shots | |

| Lead Time | Generally, mold making will take around 30 days and 7-10 days to mass production. |

| Package | The wooden packing boxes for moulds are generally inner packed in opp bags, outside packed in standard export cartons with shipping marks, and the cartons will be full of bubble bags. |

Our Advantage in Plastic Motor Damper.

● Our quality, price, and sale services are competitive.

● Long service life.

● Direct manufacturer and factory price.

● Iso certified and good guarantee.

● A strong R&D team and customised design are available to meet our customers’ high demands, product quality, and productivity expectations.

● OEM welcome.