A Guideline for Plastic Injection Molding

Plastic injection molding is a versatile and efficient manufacturing process for producing high-quality, durable plastic components. This guide explores the process, materials, and applications while highlighting DSW Plastics’ expertise in delivering tailored solutions for industries worldwide.

What is plastic injection molding?

Plastic injection moulding (U.S. spelling: injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold.

Injection moulding can be performed with a host of materials, mainly including rubber, glasses, elastomers, confections, and most commonly, thermoplastic and thermosetting polymers. Material for the part is fed into a heated barrel, mixed (using a helical screw), and injected into a mould cavity, where it cools and hardens to the configuration of the cavity.

What is plastic injection moulding?

Injection molding of plastics is a manufacturing process to mass produce identical plastic parts.

It involves forcing molten plastic or rubber material, most commonly thermoplastic and thermosetting polymers, into a mold or mould cavity, where it cools and hardens to the configuration of the cavity.

The process requires drying and mixing the polymer granules with additives, heating and moving them toward the mold with a screw and ejecting the finished part from the mold.

What is the Injection Moulding Process?

Injection molding is a widely used manufacturing process for producing plastic parts with precision and consistency. It involves several well-defined steps and relies on specialized equipment to transform raw polymer materials into finished products. Here’s a detailed breakdown of the process:

- Melt the Material

The process begins with the raw polymer granules, typically thermoplastics like ABS, nylon, or polyethylene, being loaded into a hopper. From there, the granules are fed into a heated barrel, where temperatures can reach between 200°C and 300°C, depending on the material. Inside the barrel, a helical screw rotates to mix and uniformly melt the granules into a viscous, molten state. - Inject the Molten Material into a Mold

Once the polymer is melted and homogenized, the screw pushes the material through a nozzle into a precisely engineered mold cavity. The injection occurs under high pressure—typically ranging from 10,000 to 30,000 psi—to ensure the material fills every crevice of the mold, capturing even intricate details. For example, this process can create products as small as precision medical components or as large as automotive bumpers. - Let the Material Cool to a Solid State

Inside the mold, the molten plastic begins to cool and solidify, taking on the exact shape of the cavity. Cooling times can vary from a few seconds to several minutes, depending on the material’s thermal properties and the thickness of the part. For instance, thin-walled components like food packaging cool quickly, while thicker parts like structural components take longer. - Remove the Hardened Material from the Mold

Once the plastic has solidified, the mold opens, and ejector pins or plates push the finished part out of the cavity. These ejection mechanisms are carefully calibrated to prevent damage to the product. The process then resets, ready to produce the next part in the cycle.

The Role of the Injection Molding Machine

A plastic injection molding machine is the workhorse of this process. It integrates several key components that work together seamlessly:

- Injection Unit

The injection unit houses the hopper, barrel, and screw. It is responsible for melting, mixing, and injecting the molten plastic. The screw’s design is crucial—its variable pitch ensures that material is thoroughly melted and pressurized before entering the mold. - Clamping Unit

The clamping unit holds the mold halves together under immense pressure during injection to prevent leakage of the molten material. Depending on the size and complexity of the mold, clamping forces can range from 28 to over 4,000 tons. For example, a small mold for a phone case might require 50 tons, while a large automotive panel mold might need 2,000 tons. - Control System

Modern injection molding machines are equipped with computerized control systems. These systems precisely regulate variables like temperature, pressure, and injection speed, ensuring consistent quality. They also store mold profiles for quick setup and repeatability in large production runs. - Base

The base supports all other components and houses the hydraulic or electric systems that power the machine. It includes intricate electronics and mechanical systems, such as motors and pumps, necessary for operation.

How does a plastic injection moulding machine work?

Injection molding machine is a device that uses the thrust of the screw or plunger to inject the plasticized plastic in the molten state into the closed mold cavity.

The injection moulding process works as follows:

The polymer granules are dried, mixed with additives, and fed into the barrel.

The granules are heated, mixed and moved toward the mold by a variable-pitch screw.

The screw injects the molten plastic into the mold cavity under high pressure and speed.

The mold is cooled, and the product is ejected.

The process may begin again after the plastic injecting molding machine ejects solidified plastic parts.

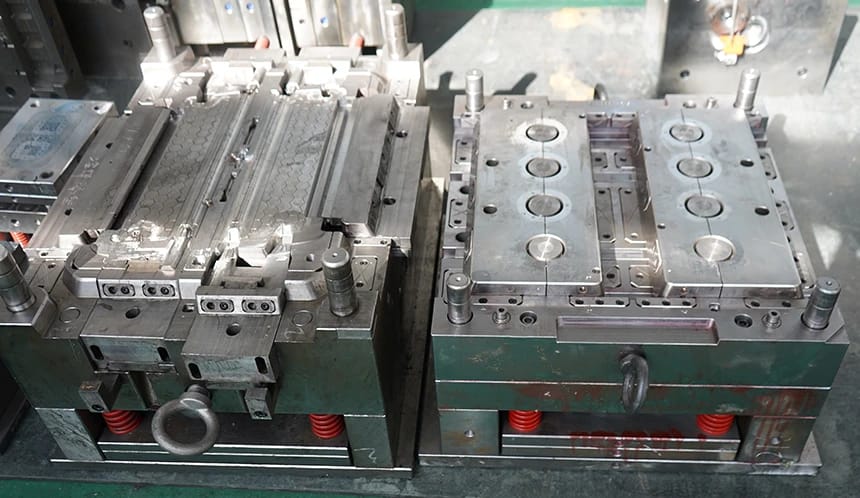

The Mold: Heart of the Process

The mold is the central element in injection molding. It consists of two halves—core and cavity—crafted with meticulous detail to form the desired part. Molds are equipped with cooling channels to regulate the temperature during the process, which is critical for minimizing defects like warping or shrinkage. For instance, a mold for a complex automotive grille might include multiple slides and inserts to achieve its detailed geometry.

By combining these components and steps, the injection molding process becomes a powerful method to produce everything from simple household items to advanced aerospace components with unparalleled efficiency and precision.

Materials Used in Plastic Injection Molding

Thermoplastics are the most commonly used materials in injection molding. They are a type of polymer that can be melted and solidified multiple times without undergoing significant chemical changes or degradation. This characteristic makes thermoplastics highly suitable for the injection moulding process, as they can be melted, injected into a mould, cooled, and repeatedly solidified to produce consistent and high-quality plastic parts.

You’ll often see thermoplastics in plastic pellet form for injection molding purposes. You can mix plastic pellets with colourants, recycled material, glitter, or other speciality additives.

The most common types of thermoplastics are:

○ Acrylonitrile Butadiene Styrene (ABS)

• ABS (acrylonitrile butadiene styrene) is a widely used material in plastic injection molding due to its desirable properties. ABS is a thermoplastic polymer that exhibits a combination of rigidity, toughness, impact resistance, and lightweight characteristics, making it an excellent choice for many applications. Did you know that LEGO bricks are made out of ABS?

○ Polycarbonates

• Polycarbonate is a transparent thermoplastic material known for its exceptional impact resistance and high level of plastic deformation without breaking or cracking. It provides optical clarity similar to glass, making it suitable for applications that require visibility or transparency, such as eyewear lenses, safety goggles, windows, and display screens. Polycarbonate is renowned for its exceptional impact resistance, which is significantly higher than that of other thermoplastics and even some metals. It can withstand high levels of impact without fracturing, making it ideal for applications that require protection against impact or vandalism, such as safety shields, protective covers, and bullet-resistant windows.

○ Nylon

• Nylon is a versatile thermoplastic material with unique electrical properties and is used in various applications, from sports equipment to industrial components. It offers a combination of strength, toughness, chemical resistance, and electrical properties, making it suitable for various demanding applications.

○ Polypropylene

• Polypropylene is a flexible material. It also has good chemical resistance and does not leach into food products, making it an ideal choice if you want to manufacture food containers or eating utensils.

○ Polyethylene

• Polyethylene is one of the most versatile plastics for injection molding. Polytheylene’s high ductility, tensile strength, impact resistance, low moisture absorption, and recyclability make it ideal for plastic containers and bags.

Wide range of Applications

Plastic Injection Molding Markets We Serve:

Plastic injection molding serves a wide range of industries, thanks to its ability to produce complex, high-precision parts in large quantities. Some of the key industries that use injection molding include:

Automotive: Injection molding is used to create a variety of automotive parts, including dashboards, bumpers, and interior components.

Medical: Precision medical devices, including surgical tools, syringes, and diagnostic equipment, are often manufactured using injection molding.

Consumer Electronics: Injection molding is widely used to produce components for electronic devices, such as smartphone housings, computer parts, and television casings.

Household Goods

Common household items such as storage containers, utensils, and appliance components are produced using injection molding, benefiting from its ability to create durable, lightweight parts efficiently.

Packaging: Plastic packaging, such as food containers, bottles, and lids, are commonly produced through the injection molding process.

Toys & Consumer Goods: Injection molding allows for the creation of durable and intricate plastic toys and household products.

Industrial and Electrical

In the industrial sector, injection molding produces components such as electrical connectors, machine parts, and plumbing fittings, all requiring durability and reliability.

Agriculture

The agriculture sector uses injection molding for farming tools, irrigation systems, and greenhouse components, ensuring durable, weather-resistant products.

DSW Plastics was established in 2004 as an injection molding and plastic part manufacturer offering assembly services at competitive prices, which can be found in automotive, alarms, dental equipment, electronics, fire safety equipment, industries, and medicine applications. We utilize German joint ventured machines with 28 to 310 clamping tons with 5-gram to 800-gram shot sizes available for all industry plastic parts.