HASCO Standard Mold Parts

HASCO standard mold parts are a cornerstone in plastic mold manufacturing. The HASCO standard dimensions have set the global benchmark for mold components, and HASCO mold bases and HASCO mold components are widely used across the industry for their precision, reliability, and performance.

What Is Hasco Standard Mold?

The HASCO standard mold refers to standardized, high-quality components based on the HASCO modular system. HASCO, a leading manufacturer of mold components, offers a wide range of components that adhere to specific industry standards to ensure precision, compatibility, and ease of use in mold-making.

Benefits of HASCO Standard Molds

Faster Production, Interchangeability,Global Availability

HASCO standard molds provide several important advantages that improve the mold-making process:

Modular Design – HASCO offers a wide range of interchangeable components that can be customized and combined to create efficient and flexible mold designs.

Easy Integration: The Hasco mold components are designed for easy integration into existing systems, helping manufacturers streamline mold-building processes.

Mold Bases: HASCO mold bases are carefully designed for perfect alignment, stability, and long-lasting use during injection or casting. Their better design keeps the mold intact, allowing it to work smoothly and consistently.

Mechanical Designs: HASCO mold parts are built to withstand harsh conditions, ensuring molds work well even under heavy stress. This careful design helps improve the molds’ performance.

HASCO mold parts are made with great accuracy and follow strict measurements. This high accuracy means the molded parts are very high quality, with few faults or flaws.

Durability: HASCO mold parts are recognized for being long-lasting. Made from strong materials, they are designed to handle tough conditions in production, which means they last longer and need less upkeep.

HASCO mold components are available worldwide through a large network of suppliers and repair centers. This worldwide access helps mold makers quickly find parts for building new products and future repairs, reducing delays.

Applications of HASCO MOLD PARTS ?

Standardization,Modular Design,High Precision,Efficient Cooling Systems

HASCO Standard Mold Parts are essential in injection mold construction, offering cost-effective, high-quality solutions across various industries such as automotive, electronics, medical devices, and consumer goods.

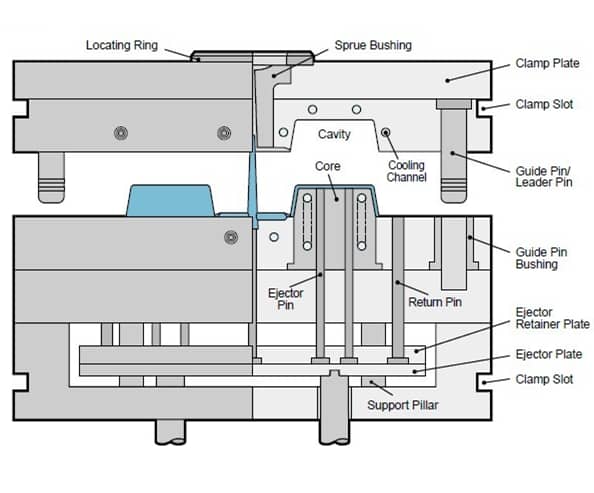

- Injection Mold Construction: Provides ready-to-use mold bases and guiding systems (guide pillars and bushes) for accurate mold assembly and alignment.

- Cooling Systems: Offers components like cooling tubes, plates, and temperature control inserts to optimize cooling efficiency and reduce cycle time.

- Ejection Systems: Includes ejector pins, sleeves, and springs to ensure smooth part ejection without damage.

- Mold Inserts: Provides core and cavity inserts for precision shaping and wear-resistant materials for long-lasting performance.

- Automation Components: Features mold clamping systems and mold flow components for secure mold operation and optimal material flow.

- Tooling and Accessories: Offers lift-out systems and customizable parts for complex mold designs.

- Precision for Specialized Industries: Ideal for medical and electronics sectors, ensuring high precision and compliance with industry standards.

Important HASCO Mold Parts

Some important HASCO mold parts help molds work effectively and accurately.

Incorporating HASCO standard mold parts into the mold-making process offers significant advantages in terms of precision, durability, and ease of maintenance. By utilizing HASCO components, DSW ensures the delivery of high-quality, reliable molds that meet the demanding needs of modern manufacturing. The global availability and compatibility of HASCO components make them an ideal choice for mold makers seeking efficient, long-lasting solutions.

Today, many mold component manufacturers in China use the HASCO components system to produce similar mold components, a practice that has become highly popular across mainland China.