Laser Cutting vs. Metal Stamping

Which Is Right for Your Project?

Metal cutting is a cornerstone of industries like automotive, aerospace, construction, and manufacturing. Among the many methods available, laser cutting and metal stamping are two of the most prominent. Each offers unique advantages and is suited to different applications. But how do you decide which is the better fit for your project? Let’s explore these methods in detail.

Laser Cutting: Precision Meets Flexibility

Laser cutting relies on a concentrated beam of light to slice through materials with incredible accuracy. Unlike traditional cutting methods, it requires no physical tools, which minimizes wear and eliminates the risk of accidental markings. At DSW Metal Products, we offer cutting-edge laser systems capable of handling materials as thick as ½-inch steel and 3/16-inch stainless steel, ensuring precision and consistent results every time.

What Makes Laser Cutting Stand Out?

- High Precision: Need intricate designs or tight tolerances? Laser cutting can achieve tolerances as fine as ±0.002 inches, perfect for industries like aerospace and electronics.

- Material Versatility: Whether it’s steel, aluminum, or stainless steel, this method handles various materials with ease. Setup adjustments are minimal, saving time and resources.

- No Contact, No Damage: Because the laser beam never touches the material, there’s little risk of deformation, making this method ideal for fragile or thin workpieces.

Where Is Laser Cutting Used?

Laser cutting is the go-to method for applications that demand precision and complexity:

- Automotive: Custom exhaust components or detailed grille designs.

- Aerospace: Lightweight panels with precise geometries.

- Signage: Elaborate branding elements and intricate lettering.

- Electronics: Housing for sensitive devices with exacting requirements.

Is laser cutting perfect for every job? Not quite. While it’s unbeatable for accuracy and versatility, it may not be the most economical option for large-scale production runs. That’s where metal stamping comes in.

Metal Stamping: Speed and Efficiency for High Volumes

When speed and cost efficiency are paramount, metal stamping takes center stage. This method uses dies to press or shape materials into desired forms, producing parts rapidly and at scale. At DSW, we specialize in high-speed progressive stamping, deep-drawn parts up to 10 inches deep, and bending sheet metal up to 3/8 inches thick.

Why Choose Metal Stamping?

- Affordable for Large Quantities: The more you produce, the lower your per-unit cost. For mass production, metal stamping is unmatched in cost-effectiveness.

- Rapid Production: Stamping can churn out thousands of parts per hour. For industries like automotive or appliance manufacturing, this speed is crucial.

- Strength and Durability: Stamped components are tough and built to last, making them perfect for structural applications.

Common Applications

Metal stamping is widely used in:

- Automotive: Manufacturing engine brackets, chassis components, and structural panels.

- Appliance Manufacturing: Producing durable housings for refrigerators, washers, and more.

- Electronics: Crafting connectors, terminals, and protective casings.

- Construction: Fabricating metal fittings and supports for structural integrity.

However, metal stamping does have limitations. For low-volume production or designs requiring high levels of customization, the upfront tooling costs can be prohibitive.

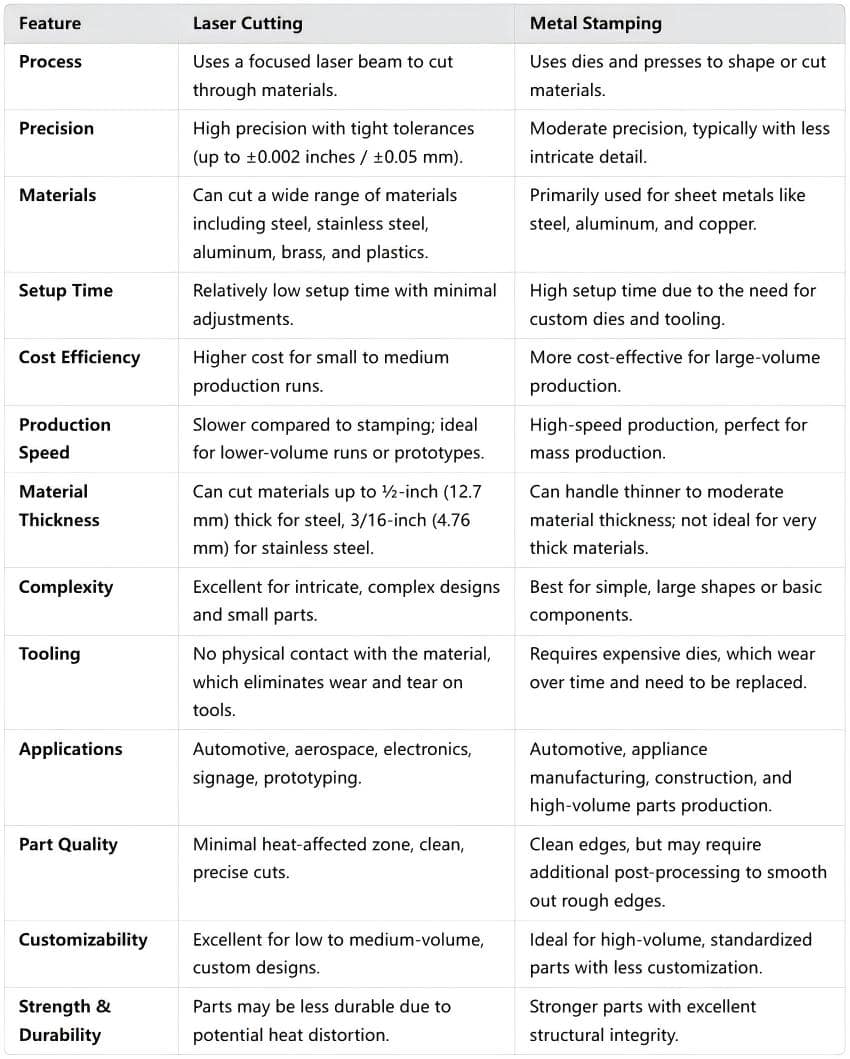

Comparison of Laser Cutting vs. Metal Stamping

Here’s a comparison table highlighting the key differences between Laser Cutting and Metal Stamping:

For very thick materials beyond 6 mm (0.25 inches), other methods like laser cutting, water jet cutting, or plasma cutting are generally preferred, as they can handle the added thickness more efficiently.

How to Choose Between Laser Cutting and Metal Stamping

The decision isn’t always straightforward. Do you need intricate designs or short production runs? Laser cutting might be the better option. Are you aiming for high-volume production with durable components? Metal stamping could save you time and money.

At DSW Metal Products, we understand that no two projects are the same. That’s why we offer both laser cutting and metal stamping services. In many cases, combining these methods yields the best results. For example, we might use laser cutting for prototypes and transition to stamping for mass production, ensuring precision and cost efficiency at every stage.

Excellence in Metal Fabrication

Whether your project demands precision laser cutting or high-speed metal stamping, DSW has the expertise and technology to deliver. With state-of-the-art equipment, a skilled team, and years of experience, we’re here to meet your needs. Ready to get started? Contact us today for a consultation. Let us help you turn your vision into reality—on time and on budget.

No comment