Polyamides (PPA): The High-Performing Plastic Material

Introduction

Polyamides (PPA) are high-performance resins and members of the nylon family, renowned for their exceptional thermal, mechanical, and physical properties.

These opaque and hygroscopic semi-crystalline materials are frequently employed in plastic injection moulding. To improve their rigidity for high-temperature applications, they are commonly reinforced with glass or minerals.

PPAs are typically used when standard nylons, like PA6 or PA66, do not meet the necessary performance requirements.

Composition and Manufacturing

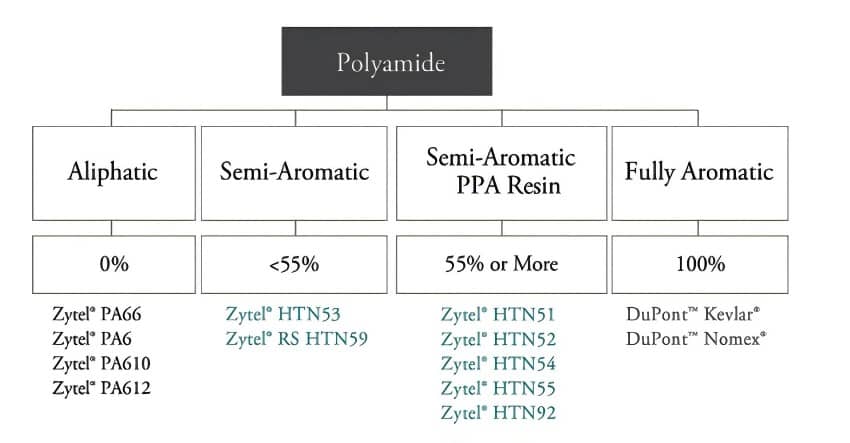

PPA material utilises terephthalic acid, isophthalic acid, or a mixture with an aliphatic diamine such as hexamethylene.

This composition generates a polymer that exhibits high degrees of rigidity, thermal stability, chemical resistance, and melting points, with a minimum of 55% aromatic content.

Characteristics

Polyamides or PPA polymers exhibit several notable characteristics:

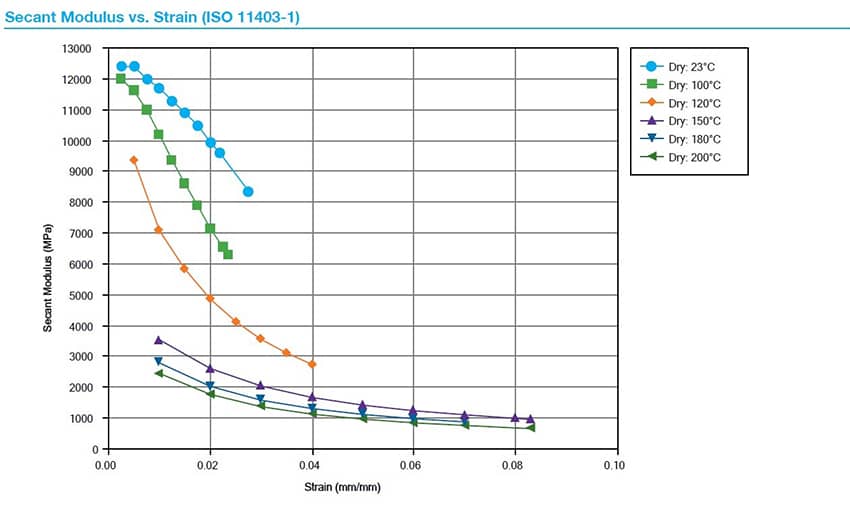

- High Thermal Resistance: PPAs offer excellent heat resistance, typically exceeding 200degC (392degF). This makes them suitable for applications subject to high temperatures, such as automotive under-the-hood components.

- Chemical Resistance: It can withstand various aggressive compounds, such as oils and fuels, rendering it appropriate for use in challenging environments.

- Dimensional Stability: PPA exhibits minimal expansion or contraction under thermal stress, ensuring precise performance. Its low coefficient of thermal expansion (CTE) ensures that it does not undergo significant dimensional changes when exposed to heat. With less expansion and contraction, PPA-based components experience reduced internal stresses and warping, which can extend the product’s lifespan.

- Low Moisture Absorption: Polyamides absorb moisture quickly; however, PPA has a meagre moisture absorption rate compared with traditional nylons like PA6 and PA66, providing more dimensional stability in humid conditions.

Applications

PPA material is used across numerous industries due to its versatile properties:

- Automotive: PPA resin is employed in critical components, including fuel systems, coolant pumps, air coolers, and LED headlamp housings. Due to its thermal endurance and chemical resistance, it is optimal for vehicle engine area applications.

- Electronics: PPA’s excellent electrical insulation and thermal resistance make it a popular choice for connectors, housings, circuit breakers, cable protection, and heat-resistant mounts.

- Medical Devices: PPA material is durable and has low moisture absorption properties. It is used in various personal care products, including toothbrushes and tubing.

- Aerospace: Lightweight and heat-resistant, PPA is used in components like bushings, valve bodies, and bearing pads in aircraft engines, where strength and temperature resistance are essential.

- Industrial Equipment: PPA is favoured for machinery parts requiring high mechanical strength and the ability to withstand extreme temperatures, such as gears and valves.

Advantages of PPA PLASTIC in Plastic Molding

PPA plastic offers several advantages in plastic injection moulding:

- High stiffness and strength

- Good heat, chemical, and fatigue resistance

- Low creep tendency and dimensional stability

- Infrared soldering environment compatibility

Disadvantages

Despite its many benefits, PPA plastic has some drawbacks:

- Not inherently flame retardant

- Requires advanced drying equipment

- High processing temperatures (up to 350°C)

- Susceptible to damage from powerful oxidants and certain acids

Technopolymers: Versatile and High-Performing Materials

Technopolymers are increasingly utilized across a wide range of applications due to their impressive characteristics, including:

- High thermal resistance

- Excellent electrical resistance

- Robust chemical resistance

- Superior wear resistance

Advantages and Strengths of PPA Polyamides

DSW choose PPA resin for their numerous benefits, including:

- Excellent rigidity at high temperatures (melting temperature of 300°C)

- Superior dimensional stability

- Strong mechanical properties

- Low moisture absorption

- Outstanding chemical resistance

It was developed to enhance the attributes of traditional polyamides like PA6 and PA66. Polyamides PPA bridges the gap between low-performance technical polymers (polyethene, polypropylene, and polycarbonate) and high-performance technical polymers. DSW regularly tests its plastic gears, confirming these characteristics and demonstrating that PPA is a viable alternative to metallic materials and other technopolymers for demanding applications.

Health and Safety

PPA is generally considered safe and unreactive. While it is toxic if ingested in large quantities, its typical applications do not pose significant health risks. PPA is not a chemical of concern, though avoiding prolonged exposure in food-related uses is advised.

Comparison with Polyamide-Nylon

PPA material is a type of nylon with enhanced properties compared to Nylon 6/6, including:

- Greater strength and stiffness

- Higher thermal capabilities

- Improved chemical and fatigue resistance

- Lower sensitivity to moisture

Conclusion

Polyamides (PPA) represent a significant advancement in high-performance plastics.

Their unique properties make them a preferred material for various demanding applications.

For more information or to discuss potential projects utilizing PPA, please get in touch with DSW.