Bulk molding Compound

or Bulk molding composite (BMC) and sheet molding compound (SMC) consist of thermosetting unsaturated polyester resins reinforced with glass fibers and typically filled with calcium carbonates.

These outstanding engineered materials are used to produce extremely durable and environmentally stable products noted for design flexibility, economical manufacturing, and resource conservation by virtue of weight reduction and low energy requirements for production. They also provide cost-effectiveness and pleasing esthetics for consumers.

DSW Industrial specializes in producing Bulk Molding Compound (BMC) and Sheet Molding Compound (SMC) products for various industries, such as electrical, rail, telecom, Industrial Equipment, and construction.

The raw material originates from IDI Composites International, USA.

SMC is a fiber-reinforced thermoset material with glass reinforcement ranging from 10% to 60%. The glass length is slightly longer than Bulk Molding Compound (BMC), typically between 1/2 inch and 1 inch (25mm).

Sheet moulding compound (SMC) contains a high percentage of glass fibres, which provide strength, stiffness, and dimensional stability to the material. The fiber content typically ranges from 10% to 30% by weight.

FEATURES

Composition: BMC is typically composed of a thermosetting resin, such as polyester, epoxy, or phenolic, mixed with a combination of fillers and reinforcements. The fillers can include mineral fillers (such as glass, calcium carbonate, or mica) and other additives to enhance specific properties.

Lightweight

BMC parts are 40% lighter than aluminium with higher tensile strengths and are infinitely less complex to fabricate than continuous fibre composites.

High Strength

BMC often contains a high percentage of reinforcements, such as glass or carbon fibers, which enhance the material’s strength, stiffness, and dimensional stability.BMCs are fabricated into complex parts through compression molding. Compression-moulded assemblies can be tailored with integrated ribs and stiffeners to carry structural loads often exceeding the load-bearing capacity of metals.

Low Shrinkage: BMC exhibits low shrinkage during the curing process, ensuring dimensional accuracy and minimizing the risk of warping or distortion.

Low Moisture Absorption: BMC has low moisture absorption characteristics, allowing it to maintain its mechanical properties and dimensional stability even in humid or wet environments.

Excellent Electrical Insulation Properties: BMC or SMC possesses excellent electrical insulation properties, making it suitable for applications requiring electrical conductivity or insulation, such as electrical enclosures or insulating parts.

Corrosion Resistance

IDI’s bulk molding compounds are resistant to solvents and corrosion. Matrices include epoxy and thermoplastic resins like PEEK, PEKK, PEI, and PPS.

Application

Bulk Molding Compound (BMC) is a durable, heat-resistant composite used across industries for its strength and versatility:

- Automotive: Lightweight parts like engine covers and housings.

- Electronics: Circuit breakers, insulators, and enclosures.

- Appliances: Oven handles and motor housings.

- Construction: Manhole covers, panels, and sewage components.

- Medical: Device housings and sterilization-resistant parts.

- Aerospace: Lightweight structural components.

- Consumer Goods: Kitchenware, sports gear, and protective cases.

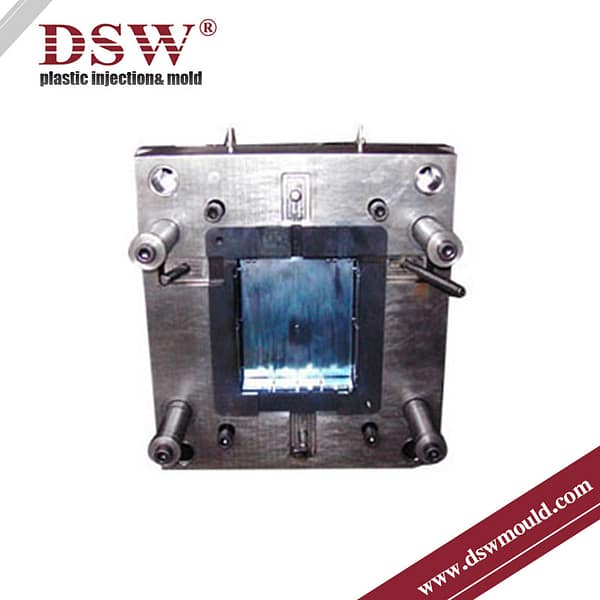

Composite compression molding

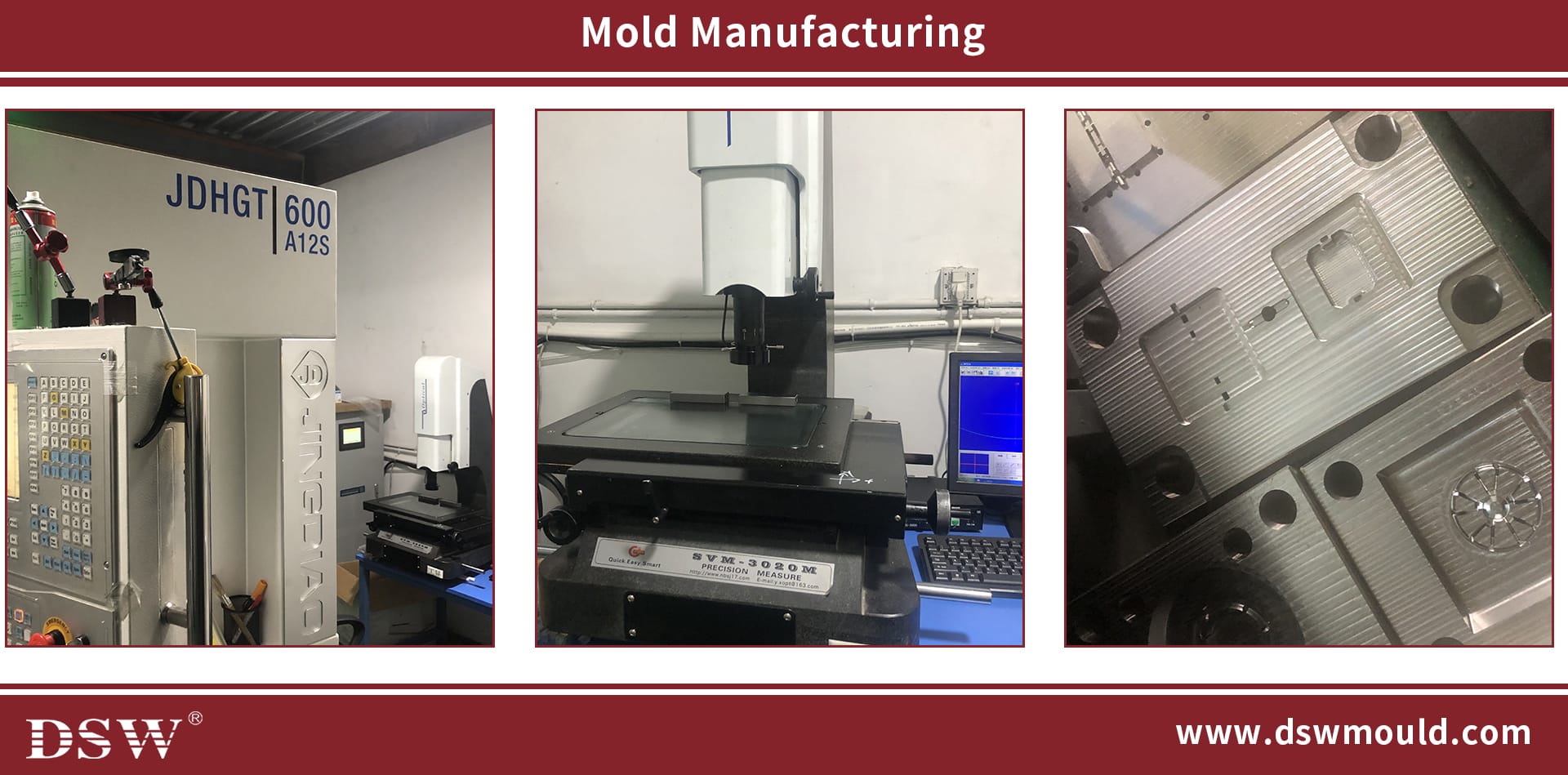

DSW Industry specializes in the design, tooling, and fabrication of complex compression molded composite parts using chopped thermoset and thermoplastic bulk molding compounds.

Composite compression molding is a manufacturing process that produces parts and components from composite materials. In this process, a composite material, which typically consists of a combination of fibers (such as fiberglass or carbon fiber) and a resin matrix (such as epoxy or polyester), is placed into a mold cavity. The mold is then closed, and pressure is applied to compress the material within the mold cavity.