Butterfly Hinge Closure cap

DSW Industry is an expert in designing and producing Butterfly Hinge Closure caps,bi-stable butterfly hinge lids, Snap-Hinge Push-On caps, and Tethered Closures with cost-effectiveness.

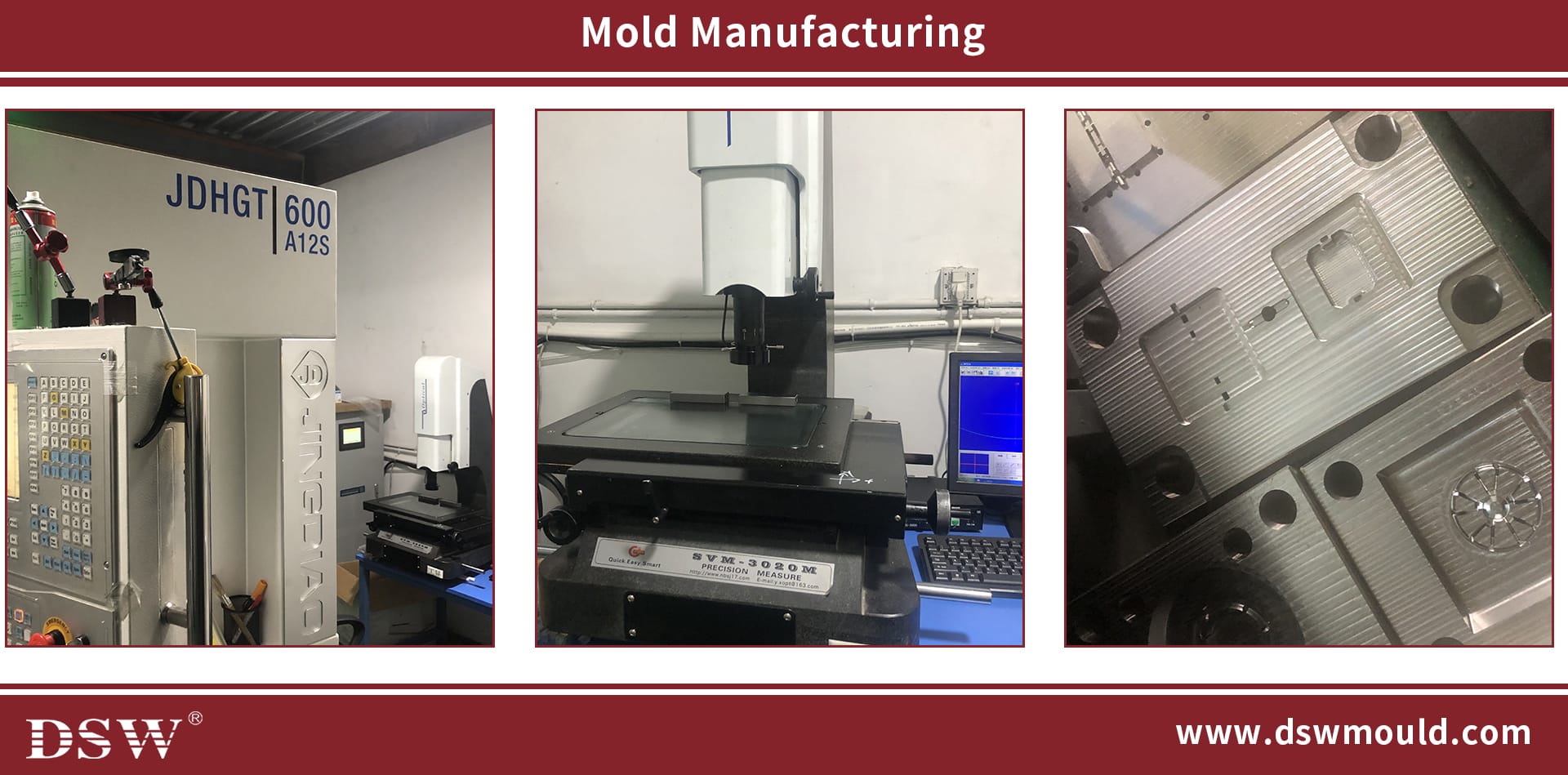

Injection molding is the cheapest way to produce parts with living hinges in high volume.

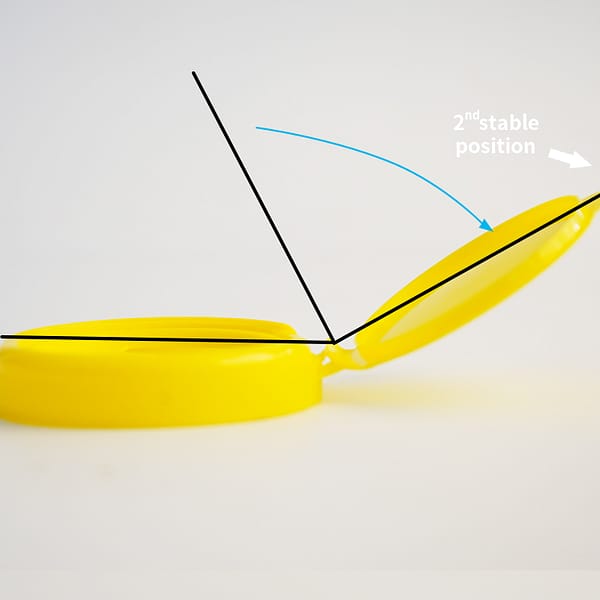

A butterfly hinge is used when you want a “bi-stable” lid action. Being bi-stable, the plastic lid will want to snap to either the open or closed position and will not stay in between.

Many different plastic lids are available, such as Screw-on caps, Flip-top lids, Push-button lids, Twist-off caps, and Continuous thread lids.

Bi-Stable Design Advantage:

Butterfly Hinge Caps feature a unique bi-stable hinge mechanism.

This design lets the lid snap securely into either the open or closed position, preventing accidental openings or spills.

It offers a user-friendly experience while ensuring product integrity.

Polypropylene: The Ideal Material Choice:

DSW’s Butterfly Hinge Caps are manufactured from 100% virgin polypropylene (PP). Polypropylene boasts exceptional:

- Flexibility: The material’s flexibility creates a bi-stable hinge without compromising strength.

- Durability: Polypropylene offers excellent everyday wear and tear resistance, ensuring long-lasting performance.

- Chemical Resistance: Polypropylene is resistant to various chemicals, making it suitable for various applications.

- Heat Resistance: The material demonstrates good heat tolerance, which is ideal for products exposed to moderate temperatures.

Extensive Applications:

DSW’s Butterfly Hinge Closure Caps cater to a diverse range of industries, including:

- Chemical

- Health & Medical

- Food & Beverage

- Household Products

Customization and Competitive Advantages:

DSW offers a wide range of customization options, including:

- Colour Selection: Choose various colours to match your specific branding or aesthetic needs.

- Decoration Techniques: Enhance the visual appeal of your caps with silk printing, UV coating, or spray painting.

- High-Volume Production: DSW’s leverage of injection moulding ensures cost-effective production for large quantities.

Quality Assurance and Customer Focus:

DSW prioritizes quality throughout the manufacturing process. They implement:

- Strict Quality Control: Multiple QC checks guarantee every cap meets their high standards.

- Vacuum Testing: This ensures a leak-proof seal, safeguarding product integrity.

DSW is dedicated to exceptional customer service, providing:

- Free Samples: Evaluate the quality and functionality of DSW’s caps firsthand.

- Technical Support: DSW’s team can answer your questions and assist with product selection.

- On-Time Delivery: Receive your caps quickly, minimizing production delays.

Partner with DSW for your Butterfly Hinge Closure Cap needs!

Contact DSW today to discuss your requirements and discover how their high-quality, bi-stable Butterfly Hinge Closure Caps can enhance your product packaging.