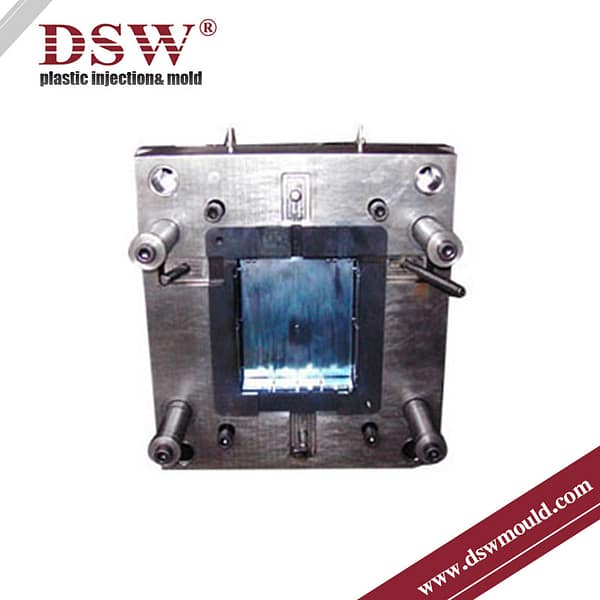

Custom-made Tooling or Molds

DSW Industry is an ISO-certified high-volume custom plastic molding manufacturer serving the medical, pharmaceutical, point-of-purchase display, and food and beverage industries.

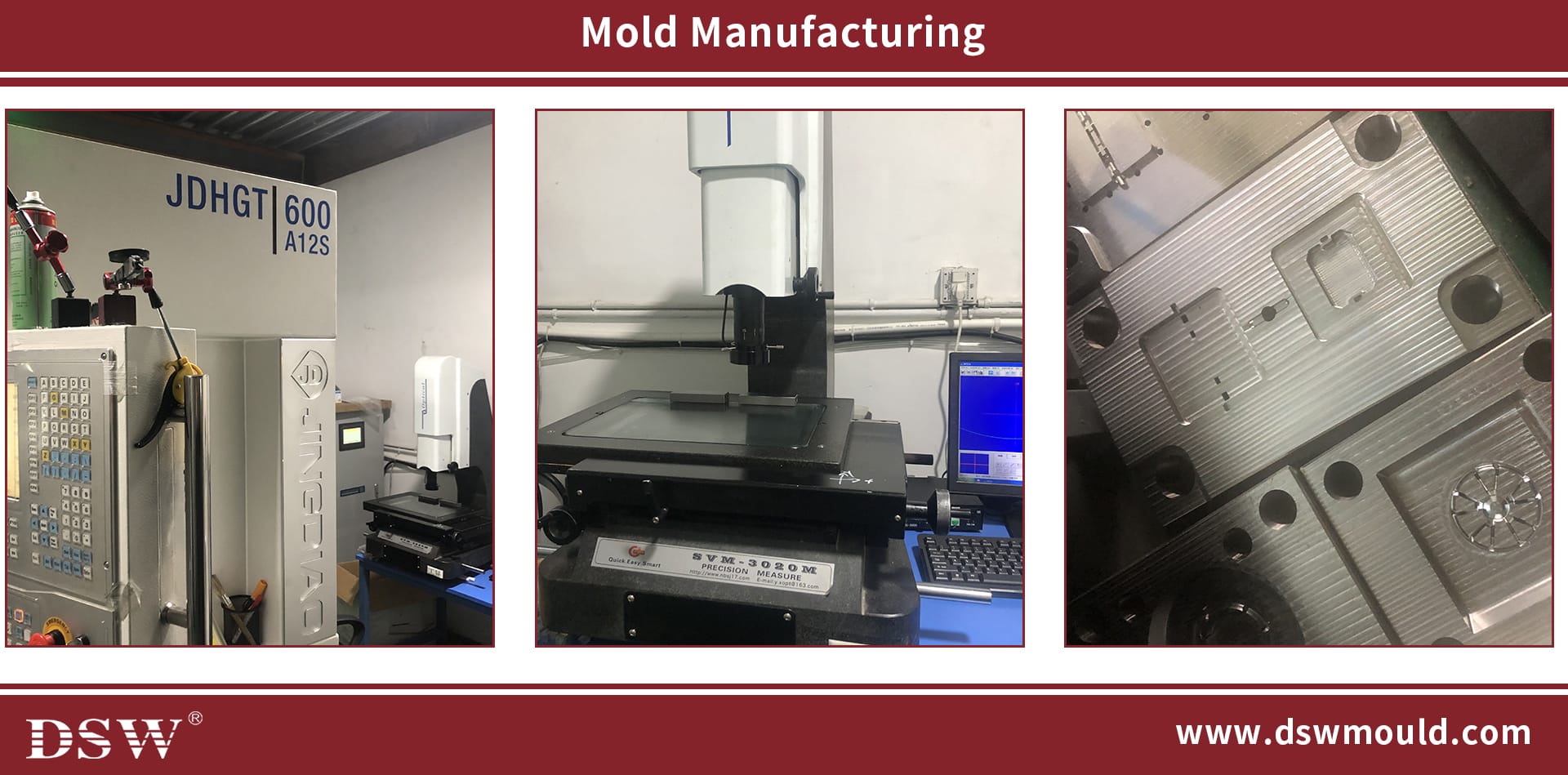

Our experienced die and tooling department personnel use their decades of combined experience in custom mold design to ensure the most precise tooling results.

For plastic injection tooling and prototyping applications, we meet your customers’ quality demands.

Custom plastic molding provides design freedom, allowing manufacturers to create complex shapes, intricate details, and custom features that may be challenging to achieve with other manufacturing methods.

It enables the production of parts with specific geometries and functionalities tailored to meet the particular needs of a product or application.

Custom Plastic Molding

| Type: | Red Roll-Stick |

| Colour: | Customized |

| MOQ: | 10000pcs |

| Packing: | Carton |

| Material: | Plastic |

| Plastic Type: | PA66+20%Gf |

| Brand Name: | DSW |

| Custom Order: | Accept |

| Model Number: | Customized |

| Color: | Customized |

| Logo: | Customized |

| OEM: | Highly Welcomed |

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

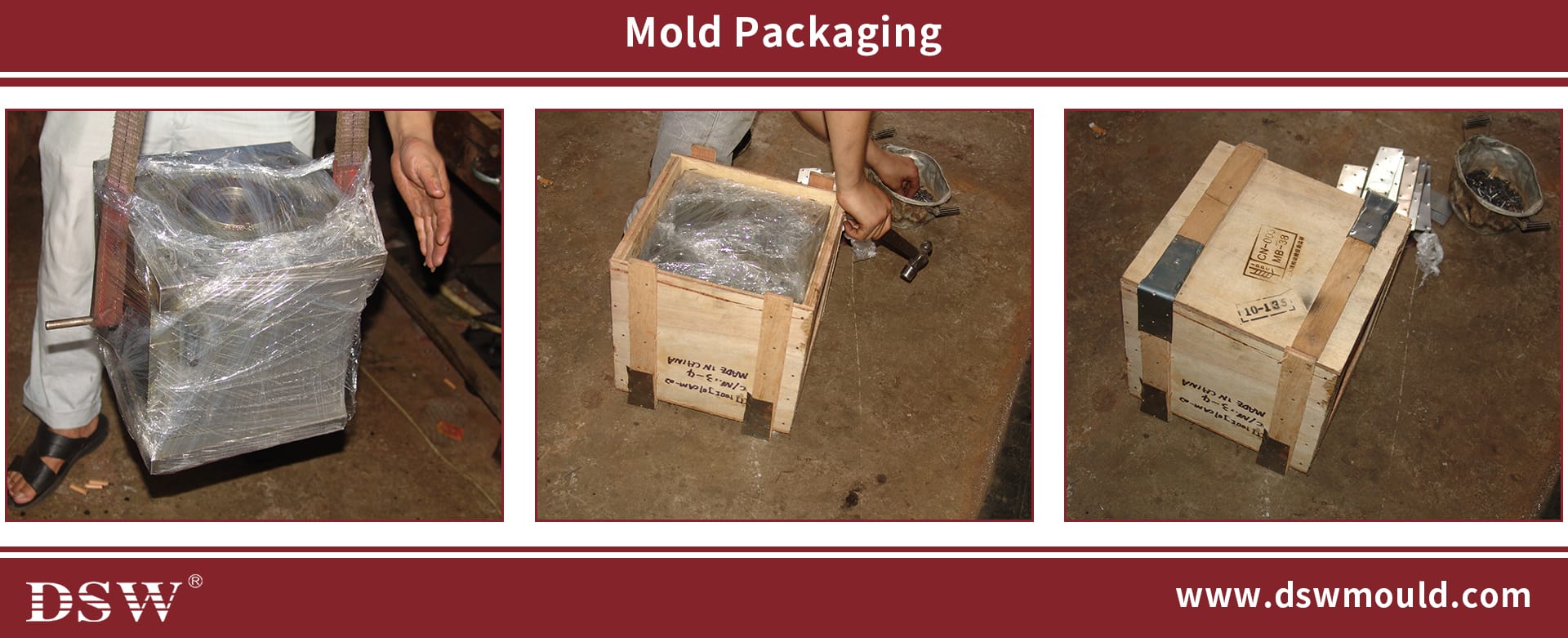

Packaging & Delivery

| Delivery Time: | Shipped in 15 days after payment |

| Packaging Details: | Export standard carton packaging |

Red Roll-Stick

| Material | 100%Virgin PP |

| Color | Any Color in Pantone/Any color available |

| MOQ | 10000pcs |

| Port | Ningbo Or Other Port |

| Delivery Time | Within 10~20 days after payment has been verified |

| Payment terms | T/T or L/C |

- Competitive pricing available.

- Environmentally friendly and recyclable materials, verified by SGS test.

- Thorough vacuum testing to ensure leak-free products.

- Dedicated team of 4 QC personnel to ensure top-notch quality.

- Excellent customer service for a satisfying business experience.

- Customized production according to your requirements.

- Wide range of colors and crafting options, including silk printing, UV coating, and spray painting, to meet your preferences.

- Committed to meeting customer needs and satisfaction.

- Over 20 years of experience in manufacturing and exporting.

Custom plastic molding finds applications in various industries. Some of the common industries that extensively use custom plastic moulding include:

Automotive: The automotive industry relies on custom plastic moulding for manufacturing components such as interior and exterior trim, dashboards, door panels, bumpers, HVAC (Heating, Ventilation, and Air Conditioning) components, engine parts, and electrical connectors.

Electronics and Electrical: Custom plastic moulding is widely used in the electronics industry to produce components like enclosures, housings, connectors, switches, circuit board mounts, and cable assemblies. It also plays a significant role in making electrical appliances, including consumer electronics and white goods.

Medical and Healthcare: In the medical and healthcare field, custom plastic moulding is used to manufacture various products, including medical device components, diagnostic equipment, laboratory consumables, syringes, packaging, surgical instruments, and implantable devices.

Packaging: Custom plastic molding is utilized in the packaging industry to produce containers, bottles, caps, closures, and other packaging solutions. Plastic packaging offers versatility, durability, and cost-effectiveness for various products, including food, beverages, cosmetics, pharmaceuticals, and household goods.

Consumer Goods: Many consumer goods, such as toys, sporting equipment, kitchenware, home appliances, and personal care products, rely on custom plastic moulding for manufacturing various components and parts.

Aerospace and Defense: The aerospace and defence industries utilize custom plastic moulding for producing aircraft and defence equipment components, including interior fittings, instrument panels, knobs, handles, and structural parts.

Industrial Equipment: Custom plastic molding is employed in the manufacturing of industrial equipment components, including machinery parts, enclosures, housings, gears, valves, and connectors.

Construction and Building: The construction industry utilizes custom plastic molding to produce items such as pipes, fittings, insulation, roofing components, window frames, and architectural products.