Injection Molding for Automotive Industry

Injection mold is a forming process using molds. Materials such as synthetic resins (plastics) are heated, melted, and then sent to the mold, which is cooled to form the designed shape.

Due to the resemblance to injecting fluids using a syringe, this process is called injection mold.

At DSW Composites, we will:

Be a partner from the prototype phase to production and post-production order fulfilment.

Provide you with process and materials experts to assist with designing particular parts and optimizing your design for injection molding.

Work with you to determine which material best suits your needs, unlocking the true potential of your design.

Evaluate the number of actions or molds needed, providing critical feedback to simplify the molds or design while keeping design needs at the forefront.

Deliver high-quality parts and finishes at high production speeds and volumes.

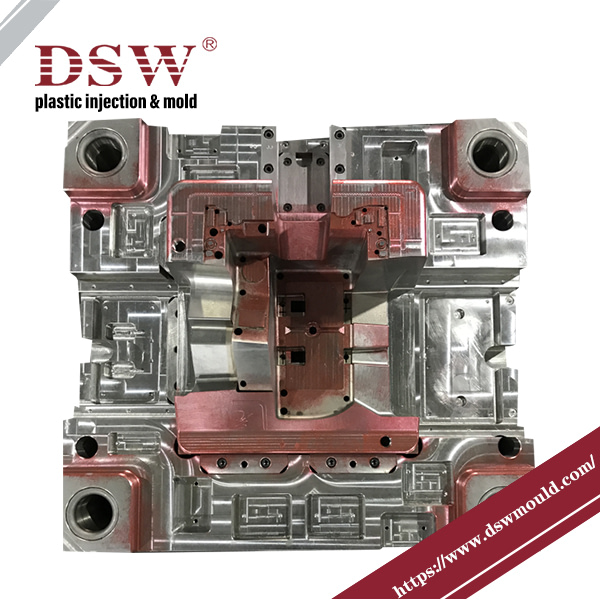

Automotive Parts Mold

| Export to(Country) | ITALY |

| Tool Description | Plastic Injection Mould |

| Material Type | ABS |

| Cavitation | 1 |

| Weight of Plastic Product | 301g/pcs |

| Mould Design by | DSW |

| Mould Construction | Standard |

| Mould Base | HASCO |

| Cav.Material | NAK 80 |

| Core Material | NAK 80 |

| Side Action | Mechanical Slide |

| Ejection | EJ pins |

| Mould Life | 500,000 |

| Molded Part Inspection By | Moulder |

Automotive injection molding

Automotive injection molding is a manufacturing process that utilizes high-pressure plastic injection to form various automotive parts, such as body panels, interior components, and engine parts.

It is one of the most frequently employed ways of mass-producing plastic parts, allowing large-scale production at competitive prices.

BENEFITS OF Automotive Plastic Mold

Now that you have a better understanding of automotive injection moulding, let’s examine some of the advantages to using injection-moulding materials:

1. Cost-effectiveness

Injection molding has quickly become one of the go-to manufacturing processes in the automotive industry, with good reason.

Its cost-effectiveness makes it highly appealing for businesses as production rates are often faster using injection molding than alternative techniques.

Injection molding helps companies reduce waste material, helping save more money and produce high-quality components at lower costs.

Automotive firms can take advantage of these benefits by investing in injection-molding machinery.

2. Speed

Making things quickly has always been important, and injection molding is an efficient and rapid way to produce parts using automated machines and computers.

It reduces both time and labor requirements in making parts.

Not only can this increase productivity, but it can also allow companies to reduce costs – an invaluable benefit in today’s highly competitive market.

3. Quality

Quality assurance in today’s automotive industry is of utmost importance, and injection molded parts offer consistently high quality for manufacturers to achieve superior results.

Using precision injection molding techniques, all aspects are uniformly thick, eliminating structural deficiencies that could pose issues later on.