Injection Molding Plastics

Injection Molding Plastics are by far the most commonly produced using injection moulding.

The process is simple in principle; a plastic material (usually a resin) is melted and forced into a mould via injection.

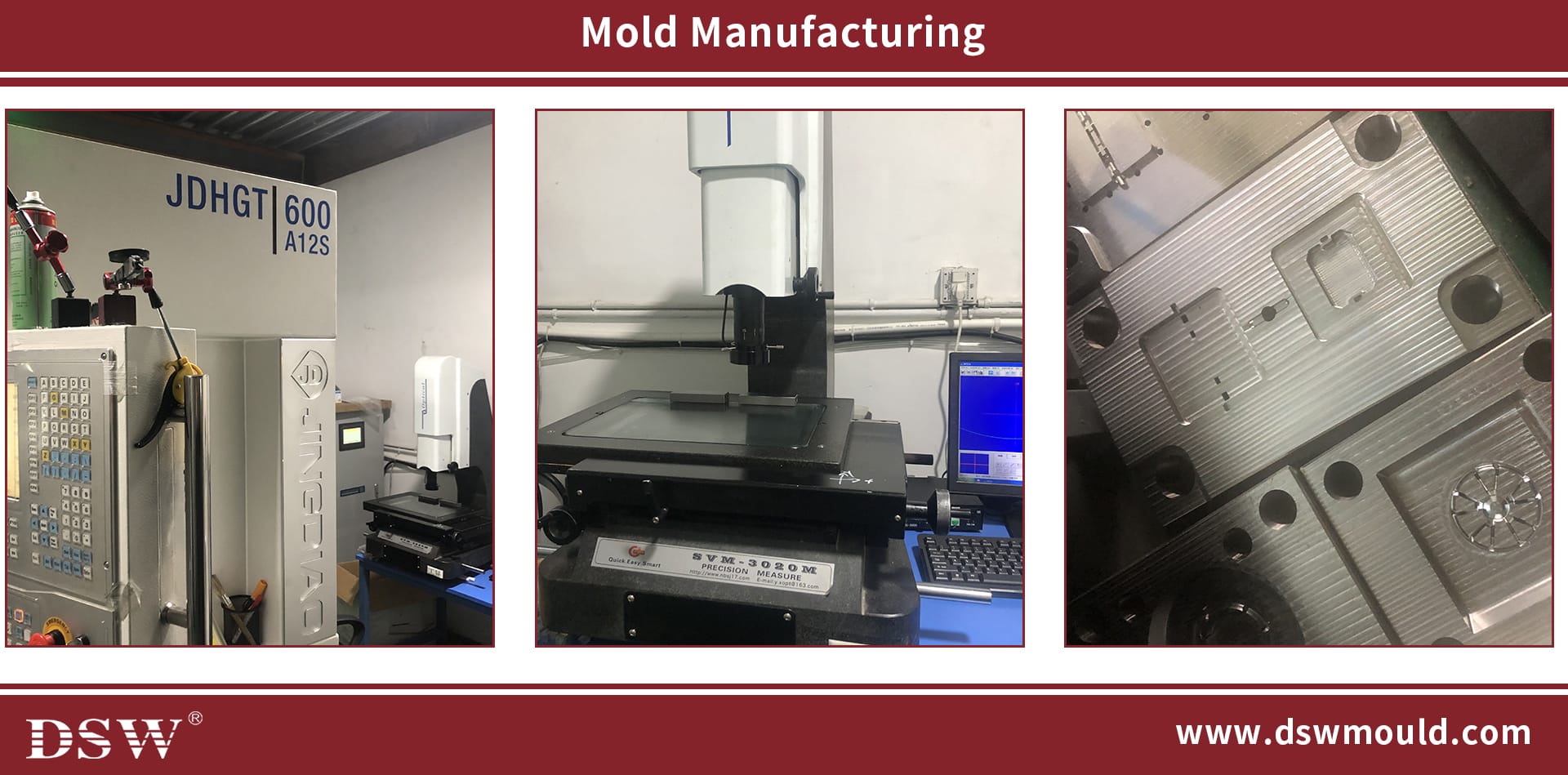

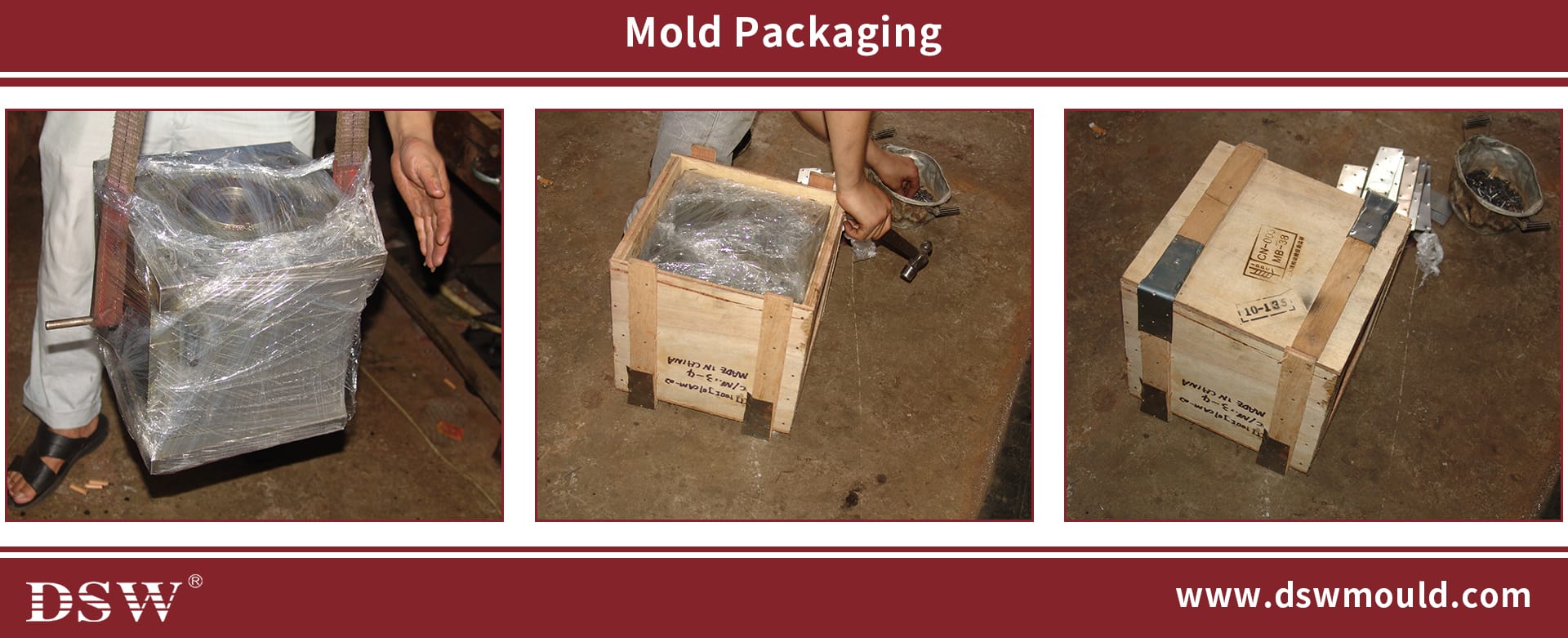

We use our decades of experience in mold and plastic to provide you with the best possible tooling for your plastic injection, prototyping and other applications.

Mold and Plastic

Plastic is a broad category of synthetic or semi-synthetic materials made primarily from polymers. It makes up much of modern life’s surface area.

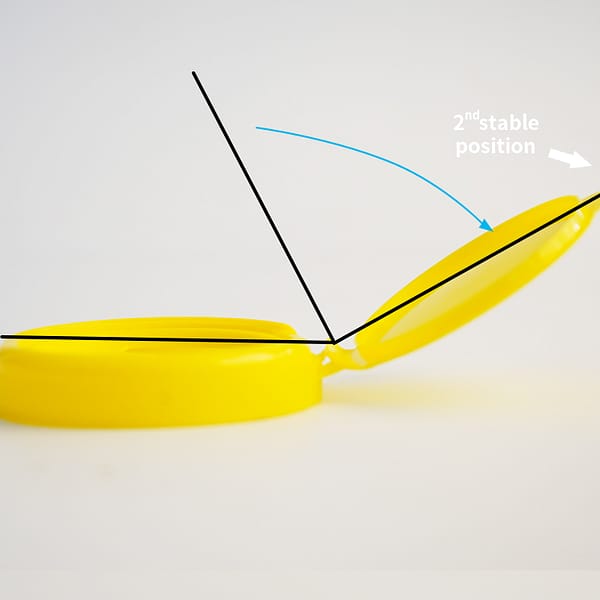

Due to their malleable nature, plastics can be formed into solid objects of various shapes using molding techniques such as injection, extrusion or pressing;

with adaptable properties like low density, electrical conductivity, transparency and toughness, plastics are used in an infinite number of products.

PLASTIC INJECTION

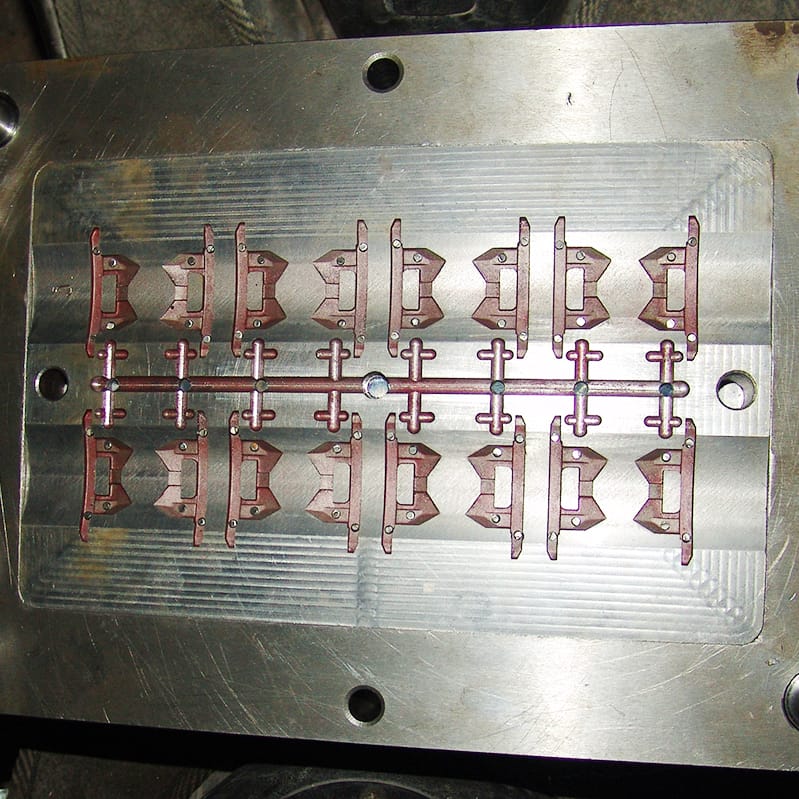

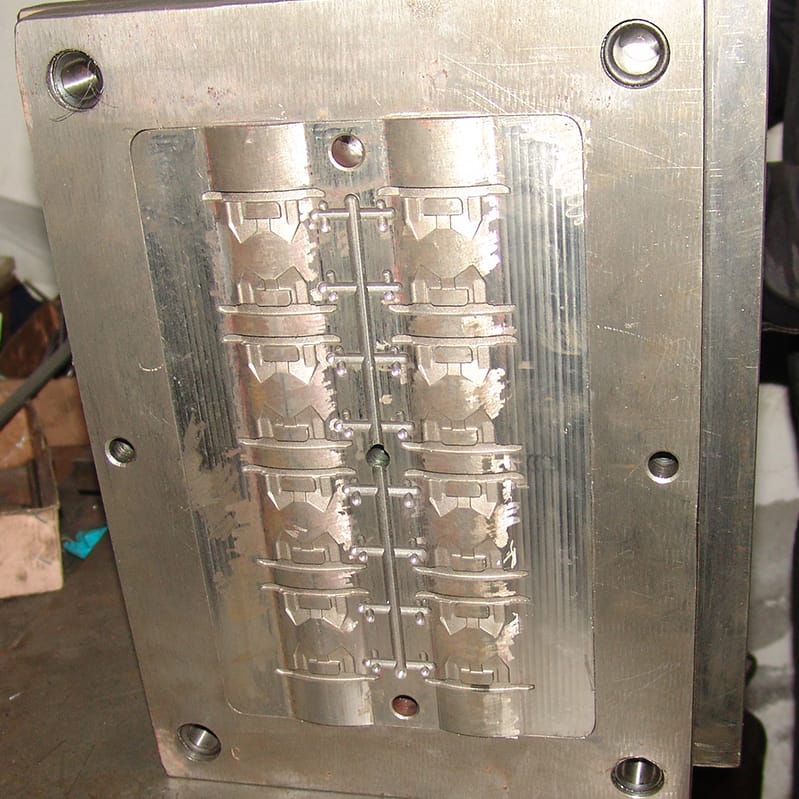

| Export to(Country) | USA |

| Tool Description | Plastic Injection Mould |

| Material Type | ABS |

| Cavitation | 1 |

| Weight of Plastic Product | 301g/pcs |

| Mould Design by | DSW |

| Mould Construction | Standard |

| Mould Base | LKM |

| Cav.Material | NAK 80 |

| Core Material | 2738 |

| Side Action | Mechanical Slide |

| Ejection | EJ pins |

| Mould Life | 500,000 |

| Moulded Part Inspection By | Moulder |