Injection Moulding Solution

DSW Injection Moulding Company is a professional designer and producer of single—and multi-cavity molds for automotive, industry, and toys.

A plastic mold makes various widely used products, including standard plastic items like bottle tops, remote control casings, syringes, and more.

It is also commonly used for manufacturing more oversized items such as car body panels.

Our experienced die and tooling department personnel use their decades of combined experience in custom mold design to ensure the most precise tooling results. We meet your customers’ quality demands for plastic injection tooling and prototyping applications.

What is Plastic Injection Moulding?

Plastic injection moulding is a manufacturing process that produces thin-walled plastic parts. Common applications include:

- Plastic housings: Found in consumer electronics, power tools, and automotive dashboards.

- Buckets and containers: Everyday items like storage buckets.

- Medical devices: Including valves and syringes.

- Toys and household goods: Such as toothbrushes and small toys.

Advantages of Plastic Injection Molding

- Forms complex shapes and refined details with ease.

- Excellent surface finish and dimensional accuracy.

- High production rates and low labor costs.

- Scrap materials can be recycled, reducing waste.

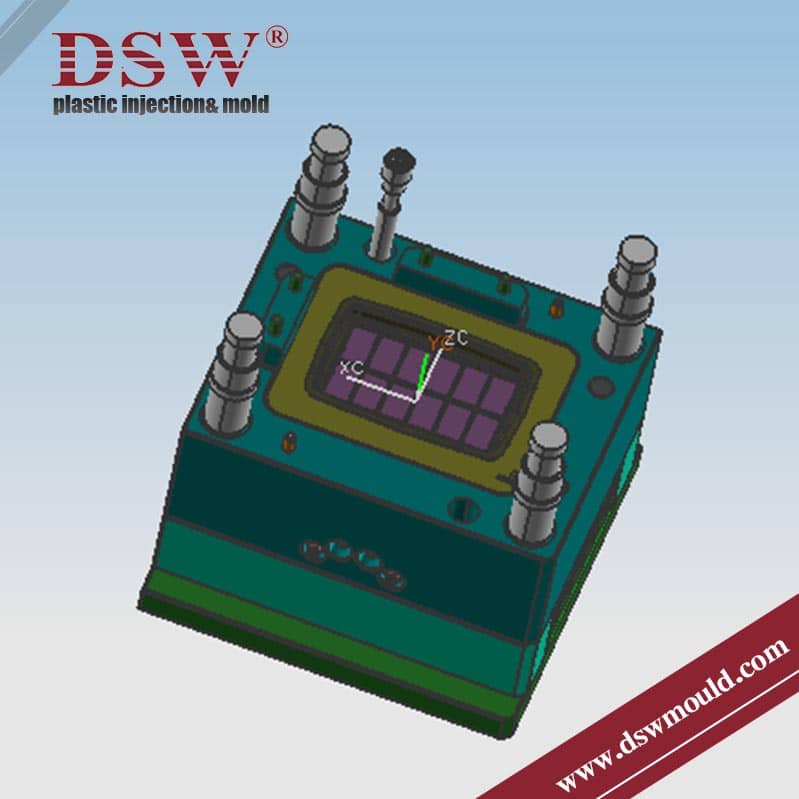

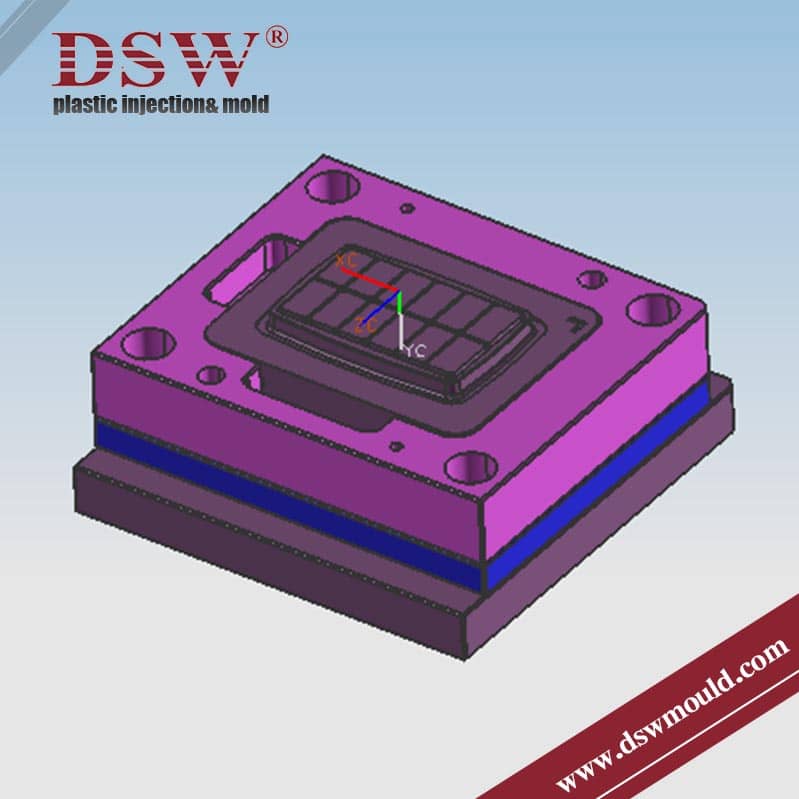

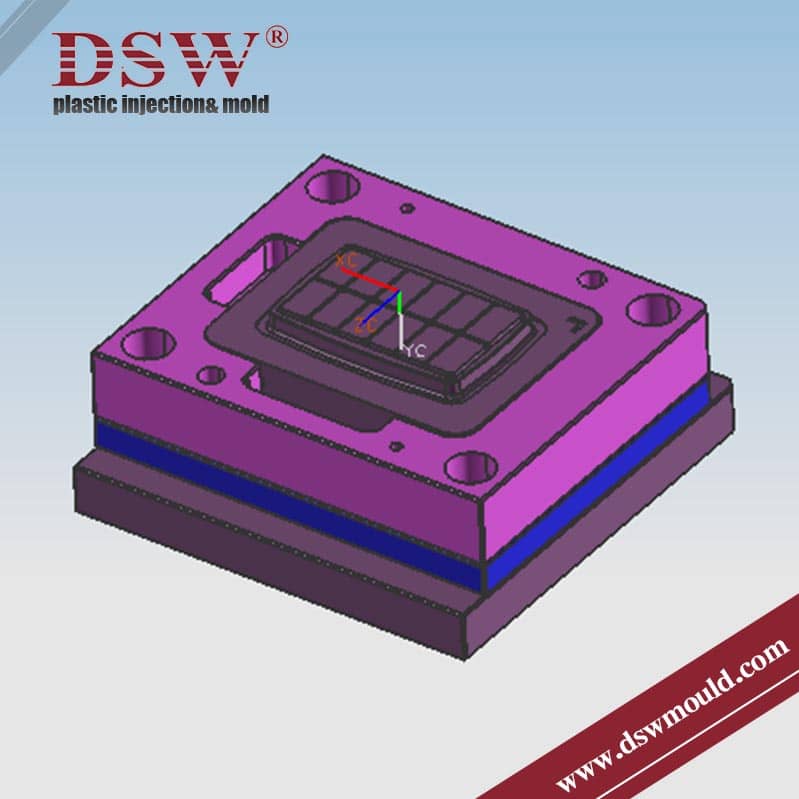

Mold Specifications

| Export to(Country) | Turkey |

| Tool Description | Plastic Injection Mould |

| Material Type | ABS |

| Cavitation | 1 |

| Weight of Plastic Product | 301g/pcs |

| Mould Design by | DSW |

| Mould Construction | Standard |

| Mould Base | LKM |

| Cav.Material | NAK 80 |

| Core Material | 2738 |

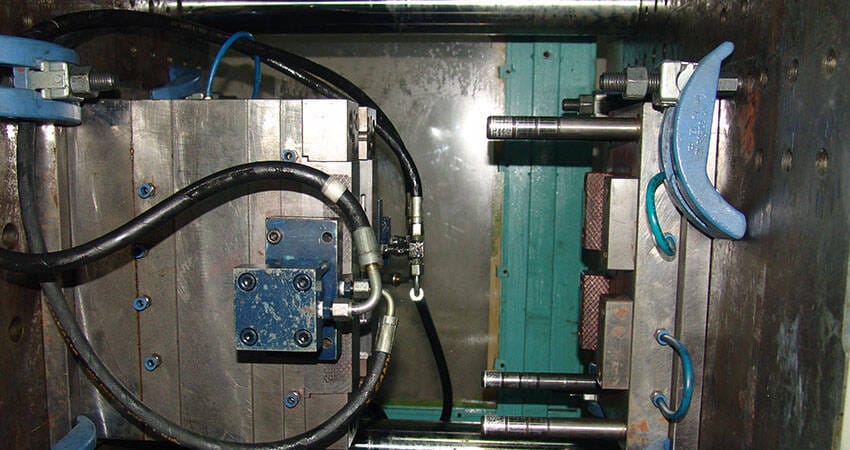

| Side Action | Mechanical Slide |

| Ejection | EJ pins |

| Mould Life | 500,000 |

| Molded Part Inspection By | Moulder |

Applications of Injection Moulding Services

Our plastic molds are ideal for manufacturing:

- Automotive parts: Dashboards, panels, and engine covers.

- Medical devices: Syringes, valves, and enclosures.

- Consumer goods: Electronics casings and household appliances.

Contact Us

Partner with DSW to develop tailored injection molding solutions. Reach out to discuss your project today!