Molded Plastic Parts

DSW specializes in manufacturing molded plastic parts and components for medical, commercial, automotive, and industrial applications.

Those plastic injection parts can be made from various materials, such as ABS, polycarbonate, polypropylene, nylon, polystyrene, polyethene, PET, and TPE.

Begin by creating a detailed design of the plastic part using computer-aided design (CAD) software.

This involves determining the part’s dimensions, features, and functionality.

Engineering considerations such as material selection, structural integrity, and manufacturability should also be considered during the design phase.

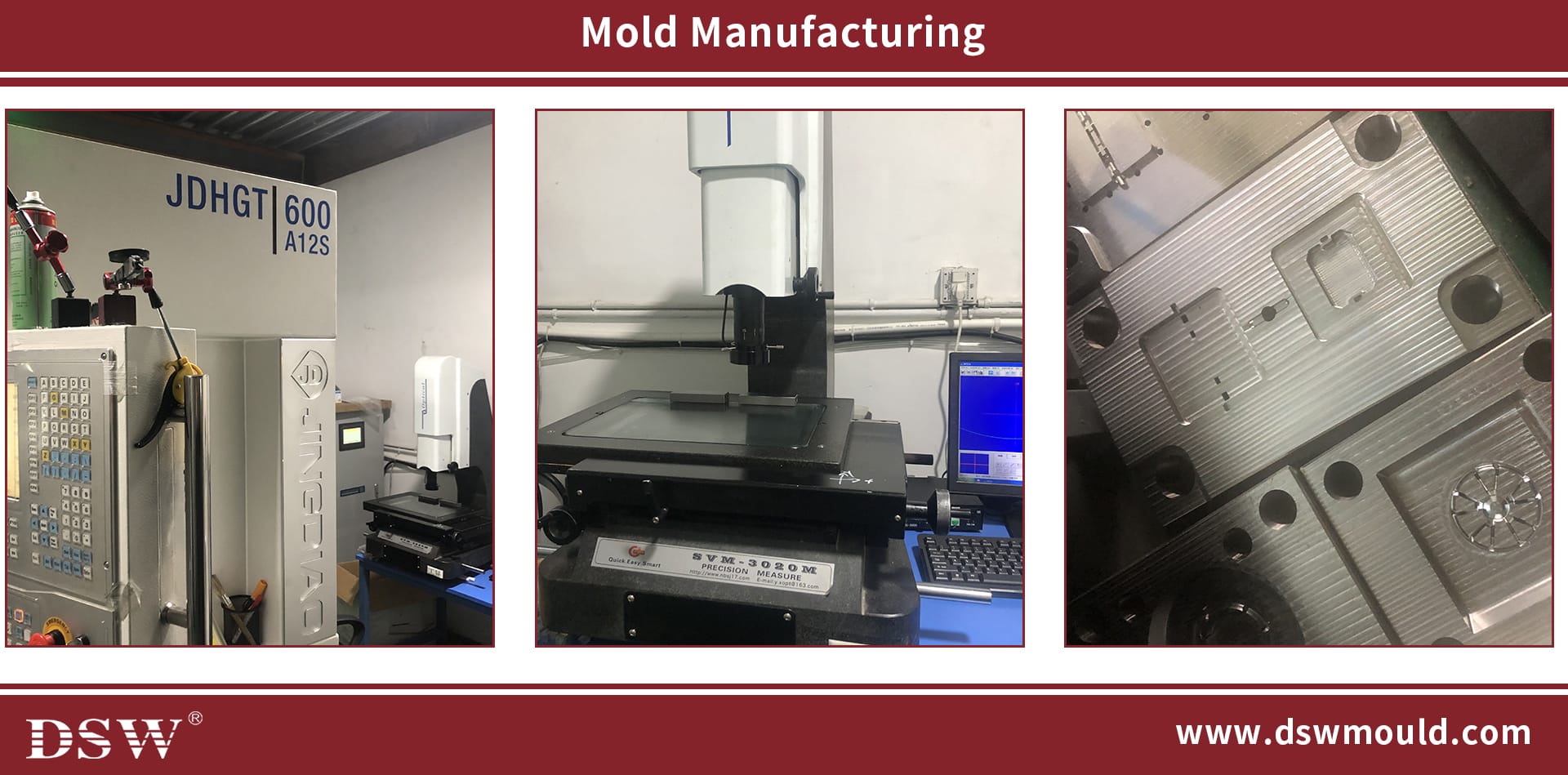

Secondly, Optimize the mold design for injection plastic parts. Consider gate location, runner system design, cooling channels, venting, and part ejection. Proper mold design ensures the part’s efficient filling, cooling, and ejection.

Plastic Moulded Parts

| Material: | Plastic |

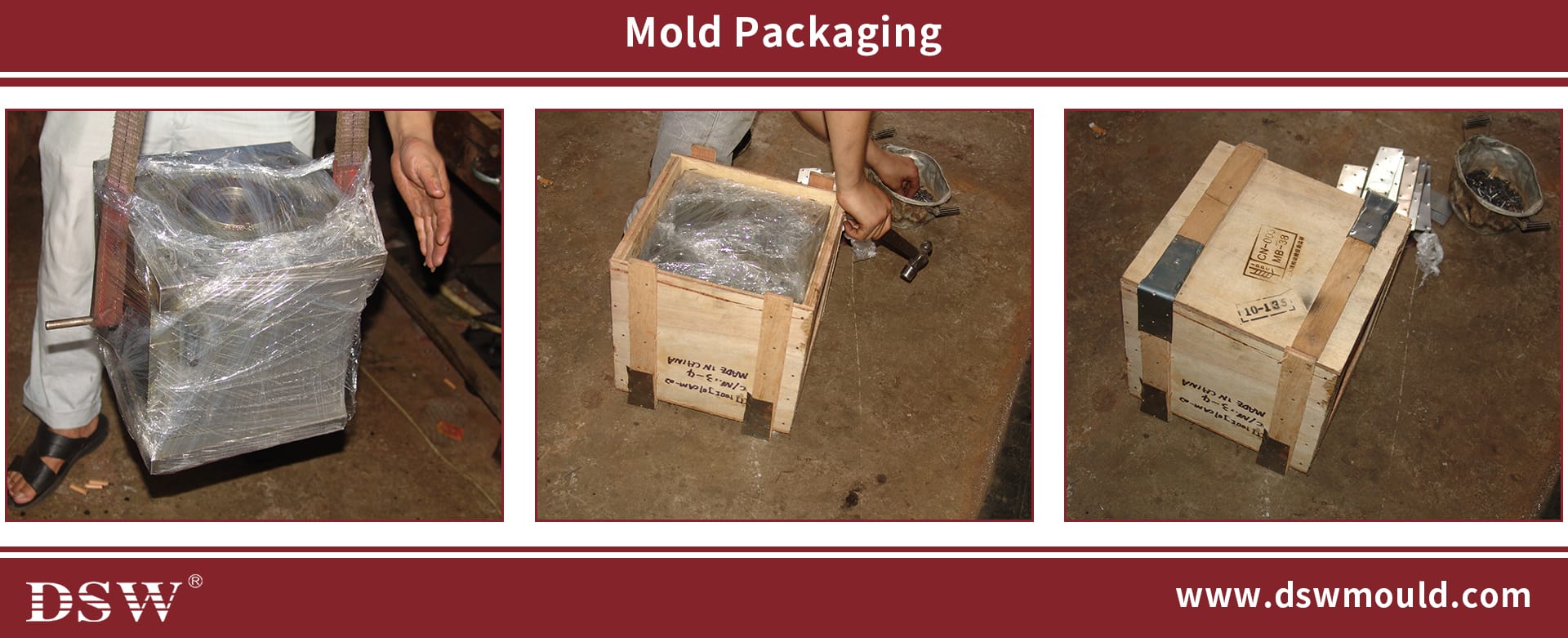

| Packing: | Carton |

| MOQ: | 5000pcs |

| Logo: | Customized |

| Sample: | Provided by Customer |

| Plastic Type: | ABS resin |

| Brand Name: | DSW |

| Payment Terms: | T/T or L/C |

| Custom Order: | Accept |

| Model Number: | Customized |

| OEM: | Acceptable |

| Colour: | Optional |

| Type: | Plastic Enclosure |

| Place of Origin: | Zhejiang, China (Mainland) |

Features of Injection Molded Parts:

Complex Geometries: Injection molding allows for producing parts with intricate and complex geometries. This includes thin walls, sharp corners, varying thicknesses, internal structures, and undercuts. The flexibility of mold design and the ability to use advanced technologies like multi-cavity molds or sliders enable the creation of parts with intricate details.

High Precision and Consistency: Plastic molding offers excellent dimensional accuracy and repeatability. Using precise molds, advanced machinery, and tight process control ensures consistent part dimensions and tolerances. This accuracy is crucial for applications that require parts to fit together precisely or meet specific functional requirements.

Plastic Selection: Injection moulding supports many materials, including thermoplastics, thermosetting plastics, elastomers, and biodegradable polymers. The material selection can be tailored to meet specific requirements such as strength, flexibility, chemical resistance, flame retardancy, or transparency. The ability to choose from diverse materials makes injection moulded parts suitable for various applications.

Strength and Durability: Molded plastic parts are known for their strength and durability. The molecular bonding during injection moulding creates a strong and uniform structure, resulting in parts with excellent mechanical properties. Injection-molded parts can withstand demanding conditions, such as high temperature, impact, and chemical exposure.

Surface Finish Options: Injection moulding offers many surface finish options. The mold surface can be textured or polished to achieve different appearances and functional properties. This includes smooth and glossy surfaces, matte finishes, textured or patterned surfaces, and various levels of glossiness. The ability to achieve specific surface finishes enhances the parts’ aesthetic appeal or functional performance.

Part Integration and Complexity: Plastic moulding allows the integration of multiple features and functions into a single plastic part. This eliminates the need for assembly or secondary operations, reducing costs and improving overall part performance. Features like threads, hinges, snaps, ribs, or bosses can be incorporated directly into the mold design, simplifying manufacturing.

Cost-Effective Mass Production: Injection molding is highly efficient for mass production. Once the mold is created, the production process can be automated, enabling the rapid and cost-effective manufacturing of large quantities of identical parts. The scalability of injection molding makes it an economical choice for high-volume production runs.

Design for Manufacturability: Injection molding offers design flexibility and ease of manufacturability. Design considerations such as draft angles, wall thickness uniformity, material flow, and part ejection can be optimized to ensure smooth production and minimize defects. Design changes can be implemented relatively easily by modifying the mold, making injection molding suitable for iterative design processes.

Low Waste: Injection molding generates minimal waste during production. The excess material can be reground and reused, reducing material waste. Additionally, the ability to produce parts with precise dimensions and eliminate the need for secondary operations or assembly processes further reduces material waste.