Nylon Molding and Electrical Systems

Nylon injection moulding is a process that creates parts from nylon, a versatile and durable thermoplastic.

Nylon provides excellent electrical insulation, high resistance to breakdown, and intense volume resistance.

Its durability, strength, and versatility make nylon ideal for numerous applications across various industries.

We offer Nylon injection moulding for fused, switchgear, and insulated fuse switches.

Our solutions cater to automotive, electrical, and electronics industries, providing comprehensive coverage for your needs.

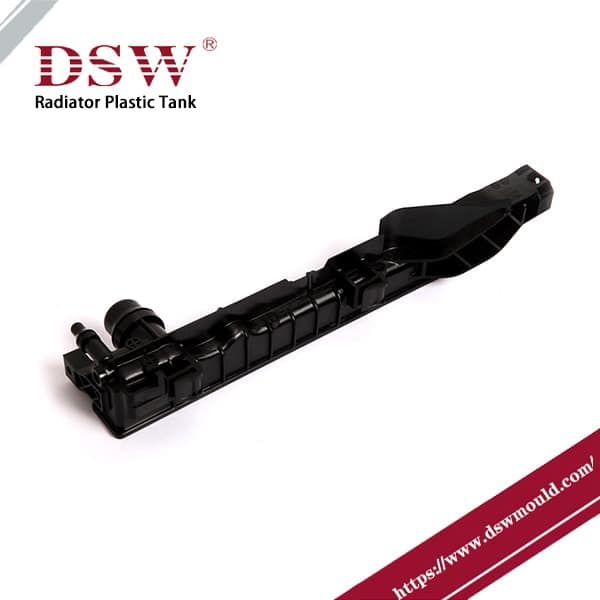

Enclosure of 400A Fuse Switch

Glass-Filled Nylon Injection Molding

Pole fuse switch disconnectors protect low-voltage networks. They combine the functions of a fuse, a switch, and a disconnector.

The fuse switch disconnector is fully insulated and features a high glass content.

Glass-filled nylon injection molding meets a range of essential requirements:

- Fully Insulated: Ensures complete electrical isolation.

- On-Load Switching Capability: Operates safely under load conditions.

- Corrosion-Proof: Resists damage from environmental factors.

- Standard Hook-Stick Compatibility: Fits standard hook-stick tools for ease of use.

- Integral Mounting Bracket: Includes a built-in bracket for secure bolting or strapping.

- Fuse Link Compatibility: Accommodates size 00 NH fuse-links or connecting links.

- Rated Operational Voltage: Supports up to 480V for reliable performance.

Features of Nylon Moulding

Material Properties: Nylon is known for its strength, flexibility, wear, and chemical resistance. These properties make it suitable for various applications, including automotive parts, consumer goods, and industrial components.

Process Overview:

Heating: Nylon pellets are heated until they melt into a viscous liquid.

Injection: The molten nylon is injected into a pre-designed mold cavity under high pressure.

Cooling: The nylon cools and solidifies in the mold, taking the shape of the cavity.

Ejection: The mold opens, and the finished part is ejected.

Advantages:

Precision: Nylon moulding produces parts with high precision and consistent quality.

Efficiency: The process is highly efficient, allowing for mass production of parts.

Versatility: Complex shapes and intricate designs can be easily achieved.

Durability: The resulting parts are solid and durable, suitable for demanding applications.

Applications:

Automobile Industry:

Blower housings

Pump housings

Power tool housings

Motor parts

Pump parts

Electrical & Electronics:

Cooling fans and fan blades

Power plugs

Gears and bearings

Belts

Electrical tool housings and parts

Power connectors

Switch sockets

Motor spools

Electronic appliances

Partner with DSW

At DSW, we offer custom nylon moulding solutions tailored for the automotive, electrical, and electronics industries.

Our capabilities include glass-filled nylon for high-strength applications and specialized enclosures for electrical systems.

Contact us to learn more about how our nylon injection molds solutions can meet your specific production needs.