Plastic Alarm Enclosure Molds

DSW leverages its expertise in custom mold design and high-precision manufacturing to deliver plastic electrical enclosures and plastic alarm enclosure molds that ensure the long-term protection of your security system’s critical components.

Our team of experienced die & tooling specialists, boasting a combined tenure of decades, translates their knowledge into the creation of the most accurate tooling available for plastic injection molding applications, including both production and prototyping of alarm enclosures.

Why Choose Us for Your Alarm Enclosure Molds?

- Decades of Expertise: Our team boasts extensive experience in custom mold design. We leverage this knowledge to create enclosures that meet your exact needs, guaranteeing a perfect fit for your alarm system.

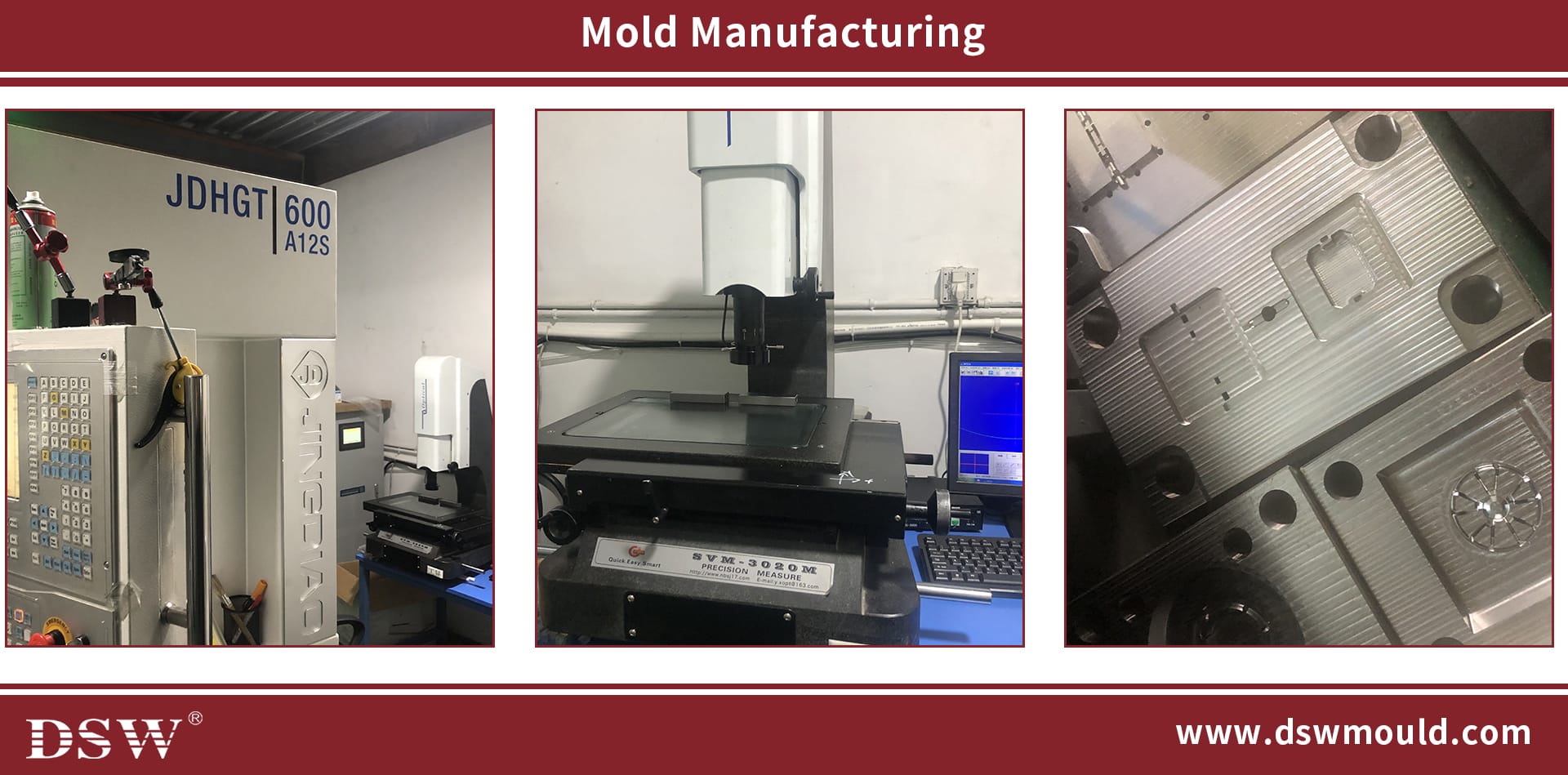

- Unwavering Precision: We understand the importance of precision in alarm enclosures. Our cutting-edge technology and rigorous quality control ensure each enclosure is manufactured to the tightest tolerances, guaranteeing optimal performance and a seamless fit.

- Superior Design Support: In addition to our mold-making expertise, we offer exceptional design assistance throughout the process. Our team will work closely with you to translate your vision into a functional and secure enclosure design, maximizing the effectiveness of your security system.

Custom Electronic Enclosures

Plastic mold featuring well-designed ventilation holes, mounting points, and cable entry points

| Export to(Country) | Europe |

| Tool Description | Alarm Enclosure Mold |

| Material Type | ABS, PA66,PC,PP |

| Cavities | 2 |

| Weight of Plastic Product | 301g/pcs |

| Mould Design by | DSW |

| Mould Construction | Standard |

| Mould Base | LKM |

| Cav.Material | NAK 80,P20,718H |

| Core Material | 2738 |

| Side Action | Mechanical Slide |

| Ejection | EJ pins |

| Mould Life | 500,000 |

| Moulded Part Inspection By | Moulder |

Built to Last with High-Quality Materials:

We use only the highest-quality materials, including ABS, PA66, PC, and PP. These materials offer exceptional strength, durability, and weather resistance, ensuring your enclosures can withstand the elements and function flawlessly, year after year.

Benefits You Can Count On:

- Enhanced Security: Our precisely designed enclosures offer a robust barrier against dust, moisture, and potential tampering, keeping your alarm system’s components safe and secure.

- Cost-Effective Solutions: Our efficient manufacturing processes translate to competitive pricing for your alarm enclosure molds. This allows you to invest in quality protection without breaking the bank.

- Long-lasting Value: Our durable molds are built to deliver millions of cycles of consistent, high-quality enclosures. This maximizes your return on investment and minimizes the need for mold replacements.

Plastic Alarm Enclosure Molds

High precision

As a highly accurate processing approach, the plastic injection molding process is able to be used to produce diversified plastic parts of almost any types. Though certain design restrictions do exist, the injection molds are made to ensure the great precision of the molded products. As a matter of fact, the precision of the finished products can be kept within 0.0008in. tolerance.

Seeking Plastic Enclosure Manufacturers?

If you’re a product designer in need of a reliable plastic enclosure manufacturer, request a quote from DSW.

We offer tailored solutions to meet your specific needs, ensuring high-quality results and exceptional service. Reach out today to see how we can support your project.