Centrifugal blowers

DSW is dedicated to delivering high-quality centrifugal blowers and plastic blower housings for various applications.

Our product offerings include air blower housings, HVAC blower housings, and centrifugal fan housings, which are suitable for HVAC systems, industrial ventilation, home appliances, and more.

Blower housings, blower casings, and housing blowers are critical components in various industrial applications.

Plastic housing of leaf blower

| Export to(Country) | Turkey |

| Tool Description | injected plastic parts |

| Material Type | PA6 |

| Cavitation | 1 |

| Weight of Plastic Product | 301g/pcs |

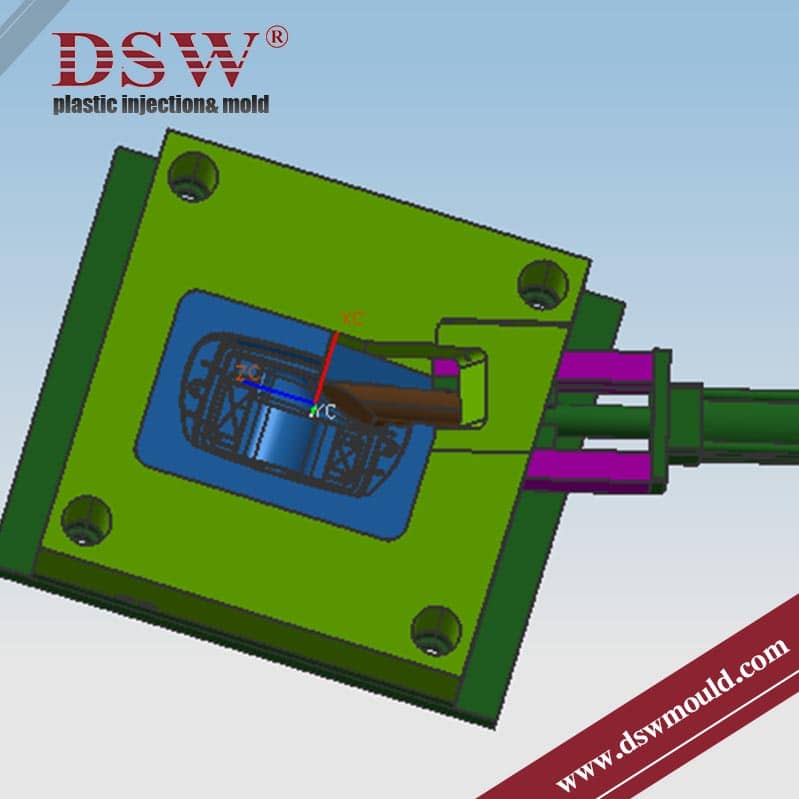

| Mould Design by | DSW |

| Mould Construction | Standard |

| Mould Base | LKM |

| Cav.Material | 55 |

| Core Material | 2738 |

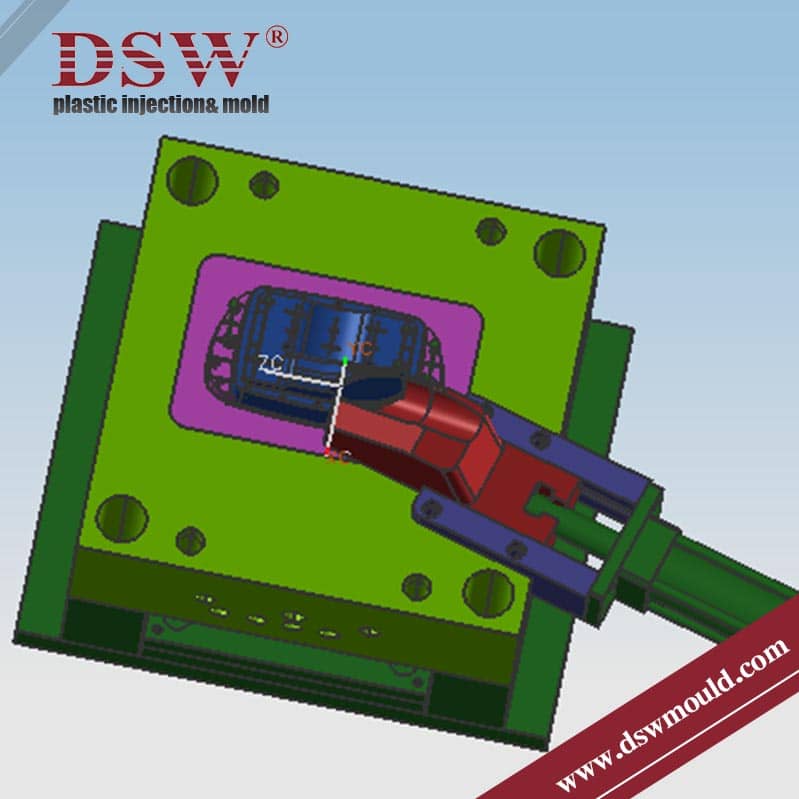

| Side Action | Mechanical Slide |

| Ejection | EJ pins |

| Mould Life | 500,000 |

| Molded Part Inspection By | Customer |

Types of Plastic Blower Housings

1. Centrifugal Blower Housings

Single Inlet Single Width (SISW): Made from PA6, PA66, or ABS, these housings are designed for single-width impellers and are commonly used in HVAC systems and industrial ventilation.

2. Axial Blower Housings

Tube Axial: Often constructed from PA6 or ABS, these cylindrical housings are used in applications requiring high airflow at low pressures, such as exhaust and cooling applications.

Vane Axial: Made from PA66 or ABS, these housings include guide vanes to improve airflow efficiency and are used in ducted HVAC systems requiring moderate pressure and high airflow.

3. Cross-Flow Blower Housings

Cross-Flow or Tangential: These housings, made from PA6 or ABS, have impellers that move air perpendicularly through the housing, providing uniform airflow across the outlet width. They are often used in air curtains and small cooling units.

Benefits of High-Quality Blower Housings

Enhanced Performance

High-quality blower housings improve the overall performance of blower systems, ensuring efficient airflow and reduced energy consumption.

Durability and Longevity

Durable materials and robust construction techniques enhance the lifespan of blower housings, reducing maintenance costs and downtime.

Noise Reduction

Optimized designs and materials help minimize noise levels, providing quieter operation in various applications.

Cost-Effectiveness

Efficient designs and reliable performance make high-quality blower housings cost-effective for various industrial applications.

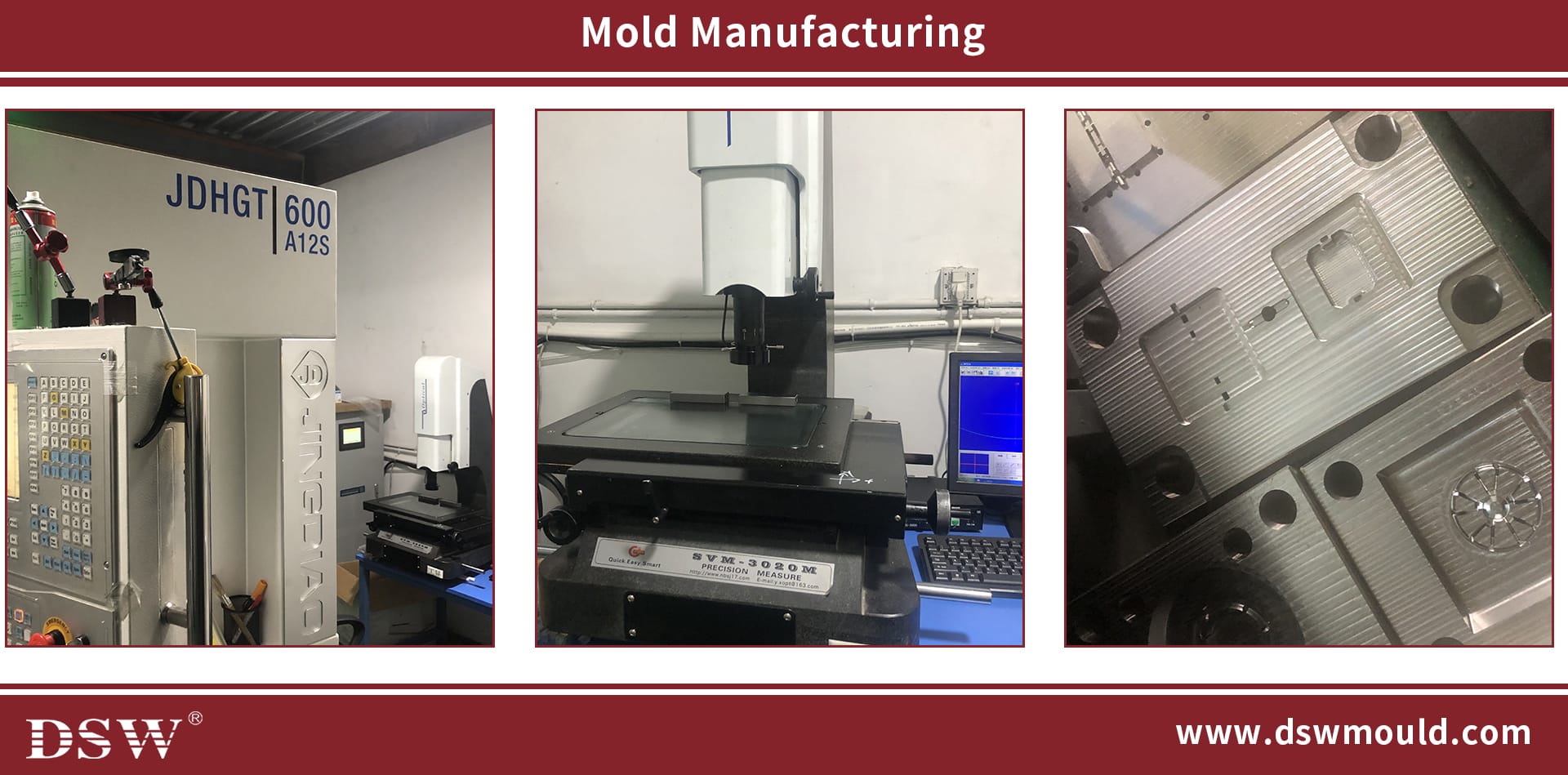

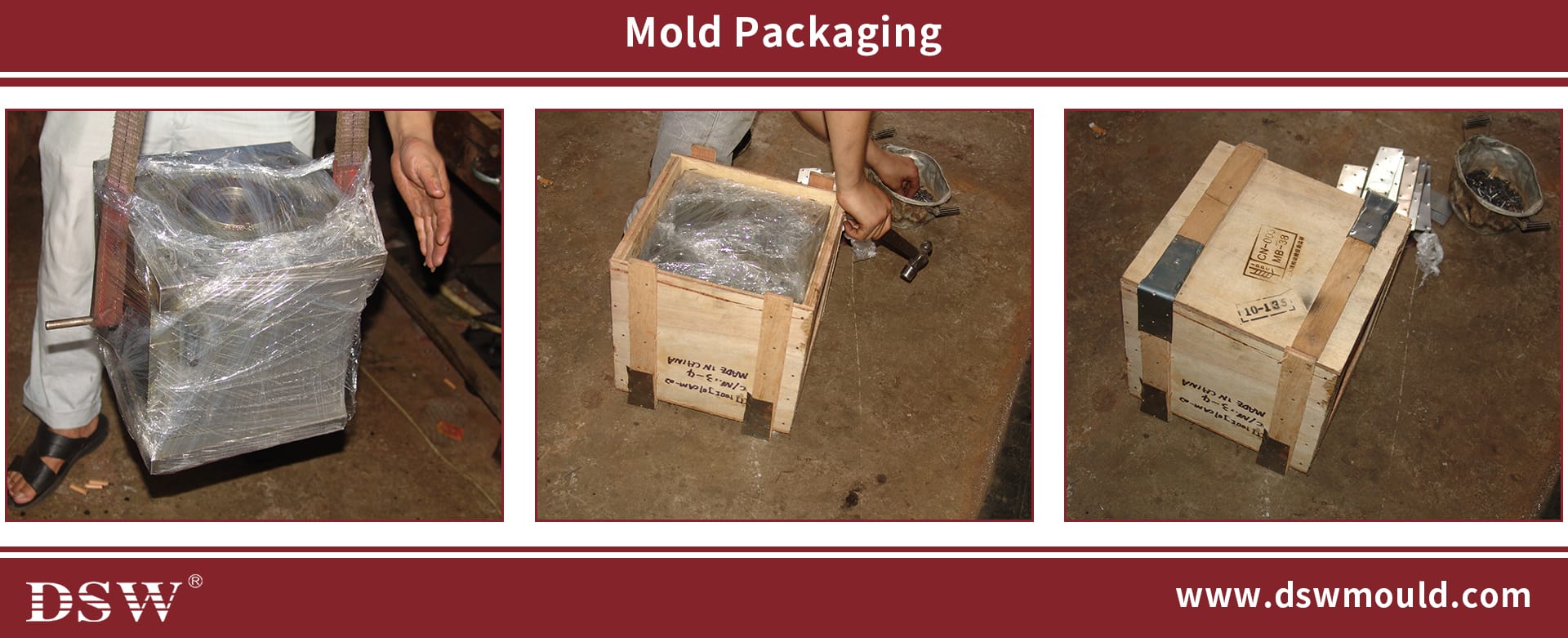

Partnering from Prototype to Production

DSW Composites collaborates with clients from the prototype phase to full-scale production, ensuring each blower housing meets specific performance requirements.

Choosing the right materials is crucial for the performance of blower housings. DSW Composites offers expertise in selecting and optimizing materials to ensure longevity and reliability.

Continuous feedback and mold simplification processes are implemented to improve manufacturing efficiency and product quality.

DSW Composites emphasizes producing high-quality blower housings with precise finishes, ensuring optimal performance and aesthetics.

DSW serves companies large and small and manufactures a comprehensive range of engineering and commodity resins to produce custom plastic components.