Plastic Molding for Plastic Food Containers

Plastic moulding, a cornerstone of modern manufacturing, is pivotal in creating plastic food containers.

This transformative method enables the efficient production of a wide array of containers vital for storing, packaging, and preserving food items.

These containers come in various shapes, sizes, and designs to accommodate food storage needs.

DSW is one of the leading suppliers in manufacturing plastic food containers for households and commercial needs.

We provide various containers in different sizes, shapes, and designs, catering to consumer and commercial needs.

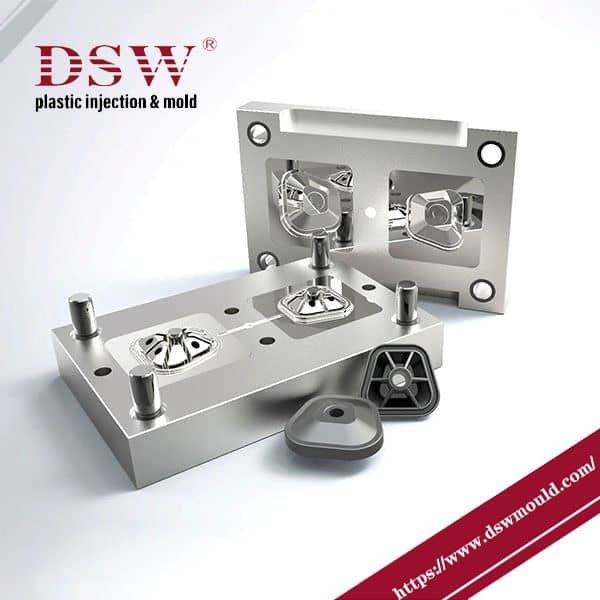

Plastic Mold for Food Containers

| PLASTIC MOLDING | Value |

| Export to (Country) | Italy |

| Tool Description | Injection Mould |

| Material Type | PC |

| Cavitation | 1 |

| Weight of Plastic Product | 301g/pcs |

| Mould Design by | DSW |

| Mould Construction | Standard |

| Mould Base | LKM |

| Cav. Material | NAK 80 |

| Core Material | 2738 |

| Side Action | Mechanical Slide |

| Ejection | EJ pins |

| Mould Life | 600,000 |

Features and Characteristics

Material: Common types of food-grade plastics used for food containers include polyethene (PE), polypropylene (PP), polystyrene (PS), and polyethene terephthalate (PET).

Versatility: Plastic containers come in many shapes, such as round, square, rectangle, and compartmentalized.

They are also available in many sizes, from small portions for individual use to family-sized containers.

Sealability: Food containers often have lids or closures that ensure a tight seal to prevent spills and leaks.

These lids protect the food from contamination and help maintain its freshness. They also make it easier to stack or store the containers.

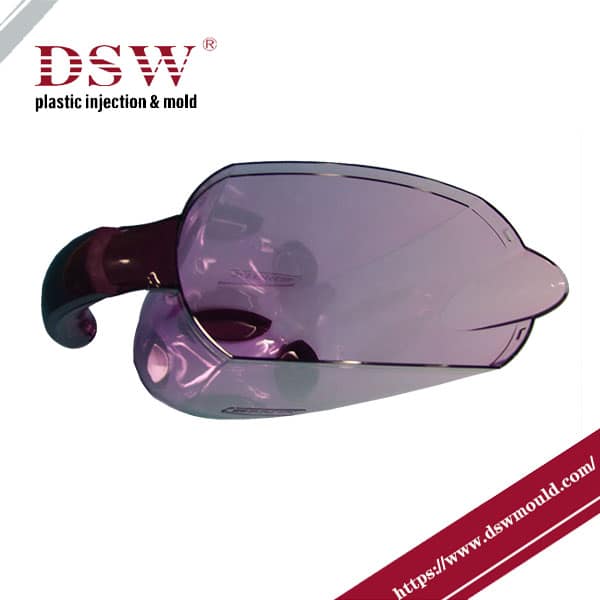

Transparency: Plastic containers for storage are transparent or feature clear sections that allow easy viewing of the contents.

It is easy to see the contents of plastic food containers without opening them.

BPA and Phthalate-Free: Many food storage containers have been manufactured without harmful chemicals like bisphenol A (BPA), phthalates, and other toxic substances.

BPA- and phthalate-free containers are often labelled “safer” for food storage.

The Molding Process: Precision at its Finest

For plastic food containers, precision and polishing are of paramount importance.

Precision: It is essential to have precise moulds for plastic food containers. Accurate mold manufacturing ensures consistency in container size, shape, and structure. A lack of precision may cause the container to be stacked incorrectly or sealed poorly. High-precision mould manufacturing is necessary to produce high-quality plastic food containers.

Polishing: The polishing treatment of mold surfaces is equally essential for the appearance and performance of plastic food containers. By polishing the mold surface, friction and adhesion are reduced, making plastic food containers easier to mould during injection moulding processing. A smooth surface on the mould ensures that the container is attractive and clean, making it easier to clean and sterilize.

In summary, mold precision and polishing are crucial for plastic food containers. High-precision mold manufacturing ensures consistency in the size and structure of the containers. At the same time, effective polishing provides a smooth mold surface, aiding in demolding and ensuring the container’s appearance and cleanliness.

In essence, plastic moulding serves as the backbone of the plastic food container industry, facilitating the production of containers that cater to the diverse needs of consumers and businesses alike. With its efficiency, versatility, and reliability, plastic moulding continues to revolutionize how we store and preserve food in the modern world.