Plastic Mold Makers

DSW is a distinguished leader in plastic mold making, specializing in precision injection molding services.

Our extensive selection of moulding materials—ABS, acetal, nylon 66, LDPE, HDPE, polycarbonate, polypropylene, and polystyrene—ensures we meet the diverse needs of various industries.

With a wealth of expertise, we excel in designing and manufacturing top-tier plastic components for automotive, industrial, consumer goods, electronics, and packaging sectors.

Product introduction

| Export to(Country) | ITALY |

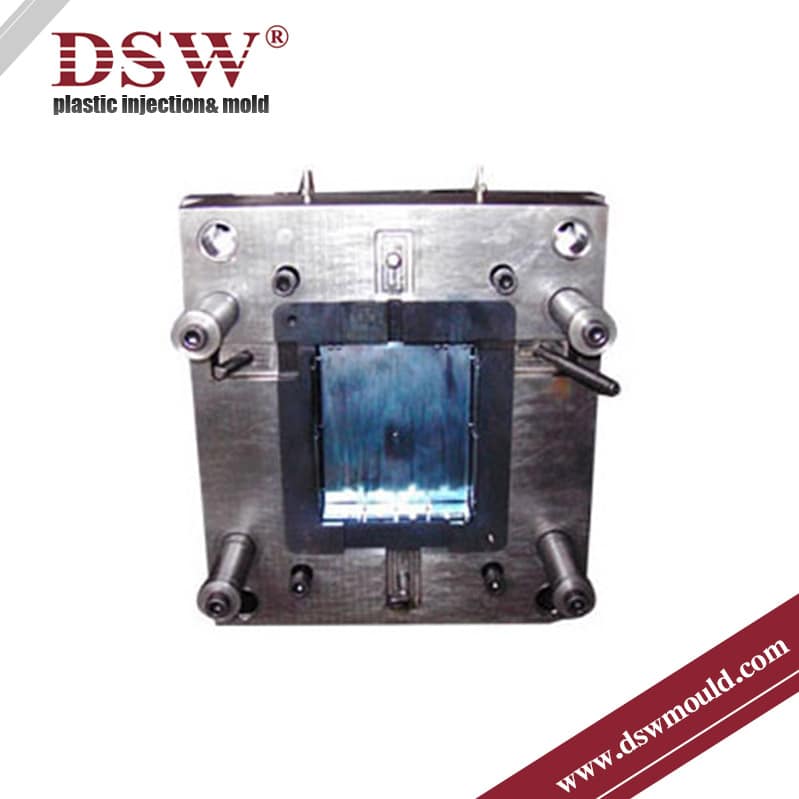

| Tool Description | Injection Mould |

| Material Type | ABS |

| Cavitation | 1 |

| Weight of Plastic Product | 301g/pcs |

| Mould Design by | DSW |

| Mould Construction | Standard |

| Mould Base | HASCO |

| Cav.Material | NAK 80 |

| Core Material | NAK 80 |

| Side Action | Mechanical Slide |

| Ejection | EJ pins |

| Mould Life | 500,000 |

| Moulded Part Inspection By | Client |

Plastic Mold Supplier:

- Competitive pricing with environmentally friendly and recyclable materials.

- Stringent quality control measures ensure product integrity.

- Customization options are available, including colour and finishing techniques.

- Dedicated customer service for a seamless business experience.

- Over 20 years of expertise in manufacturing and exporting.

Advantages of Plastic Molded Parts

BETTER MATERIALS COMPATIBILITY

Moulded plastic parts perform better than CNC-machined parts.

You can choose a precise mix of resins in your plastic composition to provide excellent chemical and solvent compatibility and corrosion resistance.

HIGH TOLERANCES AND PRECISION

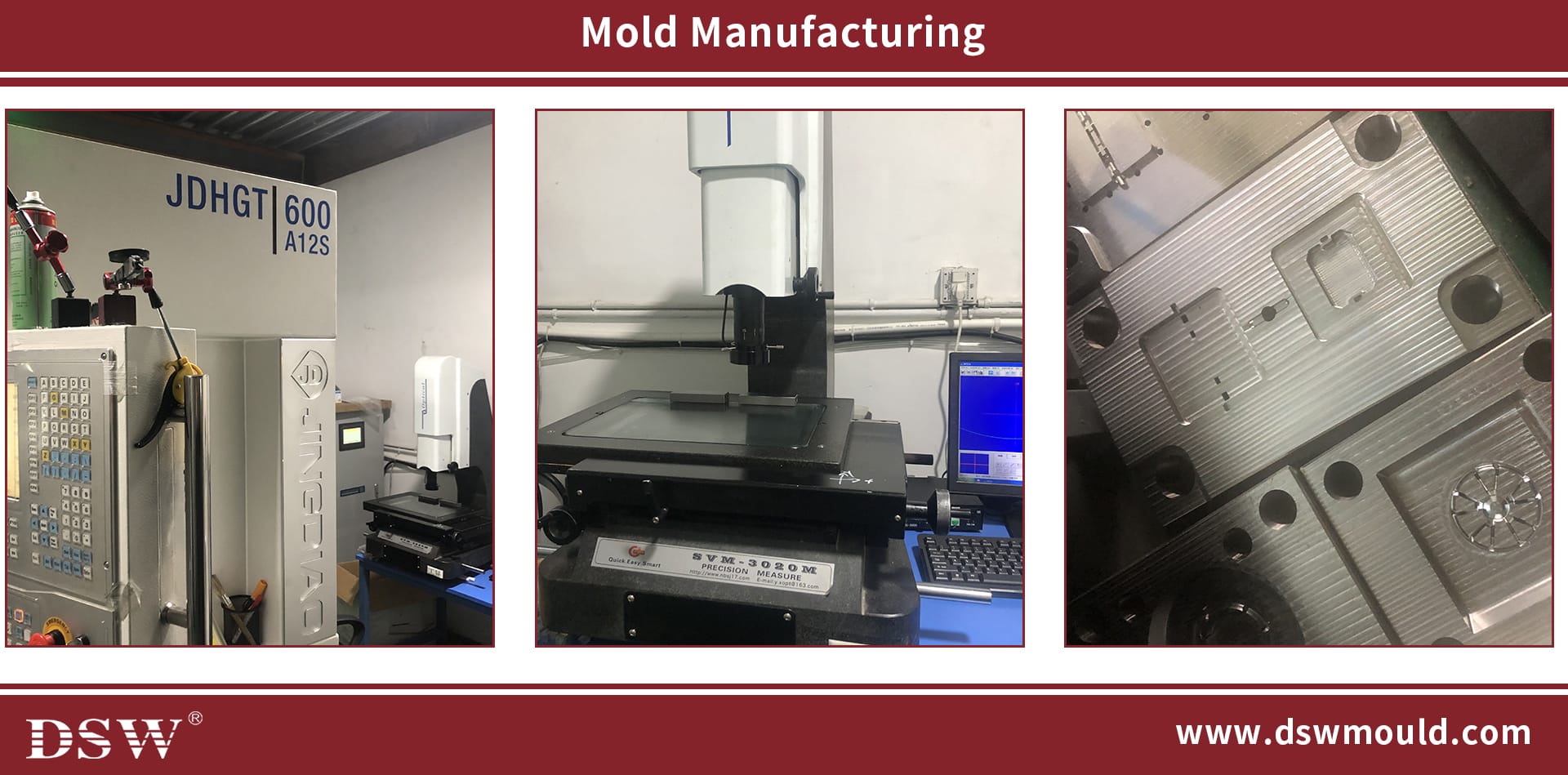

Our moulds are machined to close tolerances and deliver finely detailed features – no matter how intricate.

You’ll be able to produce millions of identical parts with the most incredible precision, accuracy, and consistency.

STRENGTH

Molding plastic parts in one piece results in more substantial parts, while trimming and drilling cause fewer quality control issues.

Parts made from injection moulding are stronger and more durable than those from CNC machining processes.

LOWER COSTS

The per-piece price is much lower with plastic injection moulding than with other manufacturing processes.

That’s especially true when you schedule large production runs, which bring down the cost per piece even more.

We can also reduce your costs by consolidating plastic parts and over-moulding to consolidate production processes.

Plastic Molded Parts

| Material | ABS |

| Color | RAL9011 |

| MOQ | 20000pcs |

| Port | Ningbo or other port |

| Delivery Time | Within 10~20 days after payment has been verified |

| Payment Terms | T/T or L/C |