SMC compression molding

Sheet Molding Compound (SMC) is a composite material used to manufacture high-strength, lightweight components for various industries, including automotive, aerospace, construction, and electrical applications.

SMC compression moulding is a versatile and cost-effective manufacturing process that produces high-quality composite parts with excellent mechanical properties and dimensional accuracy.

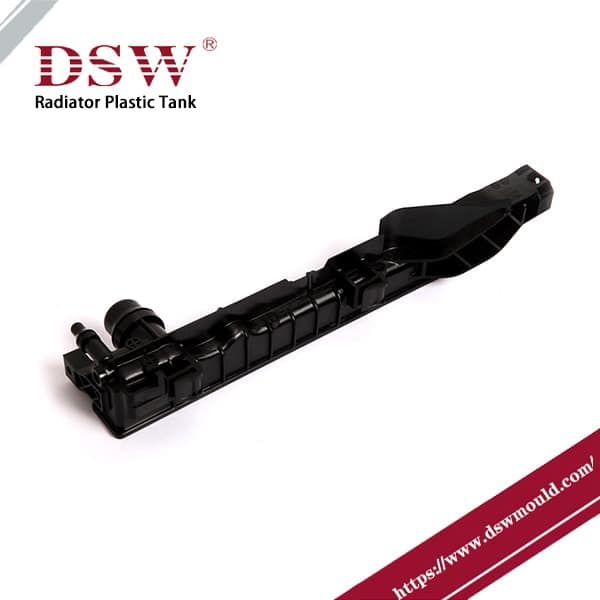

With over 20 years of experience, DSW specialize in custom SMC parts, including electronic enclosures, handles, and various industrial components.

What do we do? SMC Molding

DSW specializes in composite manufacturing and is a prominent provider of SMC compression moulding services to automotive parts suppliers and industrial firms.

We offer comprehensive solutions from design and prototyping to full-scale production, catering to various automotive, aerospace, construction, and electrical industries.

What is Sheet Molding Compound (SMC)?

SMC is a fibre-reinforced thermoset material commonly used in compression moulding for electrical components.

It comprises chopped fibreglass strands, fillers, and thermosetting resin in a sheet form.

Unlike bulk moulding compounds (BMC), SMC offers longer (around 1 inch or more) and well-distributed glass fibres, resulting in superior strength and electrical insulating properties.

Sheet Molding Compound Process

A. Pre-measured SMC sheets are placed into a heated mold cavity.

B. The mold closes under high pressure, forcing the SMC to conform to the mold shape.

C. Heat and pressure are applied, causing the resin to cure and harden the SMC into the desired part shape.

D. Once cured, the mold opens, and the finished part is ejected.

Benefits of Sheet Moulding Composite for Electrical Applications

High Strength and Dimensional Accuracy: The long fibres in SMC provide excellent strength and rigidity, while compression moulding ensures precise control over part dimensions, which is crucial for electrical components.

Electrical Insulation: SMC possesses superior electrical insulating properties, making it ideal for applications requiring high voltage isolation.

Heat Resistance: Depending on the resin type, sheet moulding composite can offer good heat resistance, essential for electrical components operating at elevated temperatures.

Flame Retardance: Certain SMC formulations can be flame retardant, adding an extra layer of safety for electrical applications.

Cost-Effective for High-Volume Production: The automated process and minimal material waste make SMC compression moulding efficient for producing electrical components.

Applications of SMC Compression Molding

Switchgear Housings: SMC’s strength and insulating properties make it suitable for switchgear housings that protect electrical components.

Insulating Barriers: Electrical panels and transformers often utilize SMC for non-conductive barriers to separate high-voltage components.

Meter Boxes and Enclosures: SMC enclosures offer durable, insulating electrical meters and other control equipment housings.

High-Voltage Busbars: Busbars, which conduct high currents, can benefit from SMC’s strength and insulating properties for support and separation.

Coil Bobbins and Housings: SMC’s ability to handle heat and maintain dimensional accuracy makes it suitable for coil bobbins and housings in electrical equipment.

SMC compression molding provides a versatile, cost-effective solution for manufacturing various electrical components. Its strength, electrical insulation, and dimensional accuracy make it a valuable material for the electrical industry.