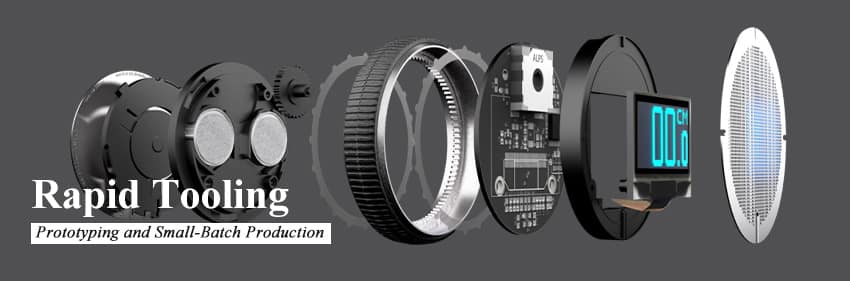

Rapid Tooling: Prototyping and Small-Batch Production

Rapid tooling has become a cornerstone of modern manufacturing, enabling fast prototyping and cost-effective small-batch production. Combining speed, efficiency, and flexibility, it is a critical bridge between prototype development and mass production.

What is Rapid Tooling?

Rapid tooling is a streamlined process for creating moulds, typically for low-volume production or rapid prototype tooling. It allows manufacturers to quickly test designs and produce parts without traditional tooling methods’ high costs and long lead times.

Prototyping allows for evaluating a product’s appearance, functionality, and manufacturability. Standard methods include 3D printing and CNC machining, which are quick and cost-effective but have limitations such as material discrepancies and difficulties producing complex shapes. Rapid tooling, essentially a low-volume injection moulding process, overcomes these challenges by allowing the testing of different materials and injection moulding issues without altering part designs.

Prototyping with Rapid Tooling

Prototype tooling enables manufacturers to evaluate a product’s appearance, functionality, and manufacturability before committing to full-scale production. Using methods like 3D printing and prototyping or CNC machining prototyping, rapid tooling allows for producing parts in materials that closely resemble the final product. Unlike other methods, rapid tooling supports more intricate geometries and diverse materials, making it a versatile choice for 3D printing rapid prototyping and design validation.

Small-Batch Production

Rapid prototyping tools provide a cost-effective solution for products with lower demand or those requiring market testing. Traditional moulds, designed for long-term use, are expensive. Rapid tooling uses less costly moulds, reducing lead times and enabling faster market entry. Known as bridge production, it is ideal for small batches where the final production volume remains uncertain. Manufacturers can enter the market faster and with reduced upfront investment by utilising rapid injection moulding or rapid prototype service.

In today’s rapidly evolving world, the pace of technological advancement significantly impacts both everyday life and the manufacturing industry. Rapid tooling has emerged as a pivotal response to these changes, offering faster and more cost-effective solutions for product development and small-batch production.

Rapid Tooling Process: Cost and Time Efficiency

Production Tooling Process

- Mold Design: A mould design is created based on the product’s CAD design, and necessary materials are ordered.

- Mold Cavity and Core: Mold cavities and cores are machined using CNC or EDM processes.

- Heat Treatment: Enhances the hardness and durability of mold components.

- Mold Assembly: Components are precisely assembled.

- Mold Surface Preparation: Texturing methods include chemical etching, electroforming, laser texturing, and manual tooling.

- Mold Polishing: Ensures a smooth, uniform surface.

- Surface Treatment (Optional): Additional coatings enhance durability.

- Mold Fitting and Testing: Ensures proper alignment and functionality in the injection molding machine.

Rapid Tooling Process

The rapid tooling process differs significantly:

- Mold Base Usage: Utilizes recycled mold bases, reducing costs and saving time.

- Material Selection: Softer materials like non-hardened steel or aluminium are used, which are cost-effective and more accessible to the machine.

- Processing Techniques: CNC machining is preferred due to its ease of working with softer materials, with EDM reserved for complex features.

- Mold Design: Optimized for cost and efficiency, favour simpler designs for low-volume production.

Compared to conventional tooling, rapid prototyping models use recycled mold bases and simplified designs to reduce production time and cost significantly.

Comparison: Rapid Tooling vs. Conventional Tooling

| Aspect | Rapid Tooling | Conventional Tooling |

| Speed | 7-15 days | 4-8 weeks |

| Tooling Cost | Low overhead costs | High overhead costs |

| Ideal Production Volume | 1,000-30,000 parts | ~30,000+ parts |

| Applications | Product Validation, bridge tooling, short-run production | Mass production |

Advantages and Disadvantages of Rapid Tooling

Advantages:

- Speed and Efficiency: Significantly reduces mold creation time.

- Cost-Effectiveness: Lower initial costs and faster production reduce overall expenses.

- Design Flexibility: Allows for modifications even after tooling begins.

- Material Selection: Supports a wide range of materials.

- Customization and Prototyping: Ideal for diverse and specific product designs.

Disadvantages:

- Limited Tool Life: Softer materials result in a shorter lifespan.

- Material Constraints: Fewer material options compared to traditional tooling.

- Complexity: Challenges in producing highly intricate designs.

- Tolerance and Precision: More challenging to achieve tight tolerances.

- Volume Limitations: Less efficient for very high production volumes.

Innovations in Rapid Tooling: Metal 3D Printing

Metal 3D printing transforms the creation of mold cores and cavities by enabling intricate geometries that are not possible with traditional methods. This technique supports rapid prototyping and the application of rapid prototyping in industries like automotive and aerospace. However, post-processing is often required, and costs may exceed conventional techniques.

Conclusion

Rapid tooling bridges the gap between prototyping and mass production, offering manufacturers a fast, efficient, and cost-effective way to test designs and produce parts in small quantities. As rapid prototyping companies continue to innovate, technologies like 3D printing rapid prototyping and rapid injection molding will drive further advancements in manufacturing, making the process even more accessible and versatile.

Rapid tooling is invaluable for modern manufacturing, whether you’re developing a prototype or preparing for small-batch production.

No comment