Injection Molding: Thermoplastics vs. Thermosetting Plastics

Injection moulding is a popular manufacturing process for creating a wide range of products, from automotive components to everyday household items. Two main types of plastics are commonly used in injection moulding: thermoplastics and thermosetting plastics. Understanding the differences between these materials is crucial for selecting the right type for specific applications. However, compression moulding is the most common method for thermosetting plastics, offering high strength and heat resistance for final products.

What is the Difference Between Thermoplastic and Thermosetting Plastic?

Thermoplastics and thermosetting plastics are two distinct categories of polymers, each with unique properties and applications due to their different behaviours under heat.

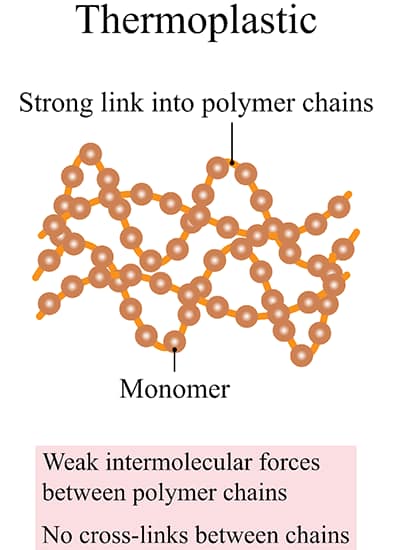

Thermoplastics can be heated and melted multiple times without changing their chemical structure. They are made of linear or slightly branched chains without cross-links, allowing them to flow easily when heated. Polyethene is used in bags and bottles, polypropylene in packaging and automotive parts, and polystyrene in foam products and disposable cutlery. The ability of thermoplastics to be recycled and reformed makes them a popular choice for applications requiring versatility and ease of processing.

Thermosetting plastics, on the contrary, are plastics that undergo chemical transformation when heated. The curing process forms permanent cross-links or irreversible bonds between polymer chains. These plastics cannot be melted, reshaped or re-cured once cured. Some examples include epoxy resins used in adhesives and paints, phenolic resins used in electrical insulations, and melamine, which can be found in kitchenware. Thermosetting materials are characterized by their structural integrity, high chemical resistance and thermal stability. They are ideal for applications that require durability and heat resistance.

Common Materials

For thermoplastic and thermosetting plastics

Thermoplastic Materials

- Polyethylene (PE): Used in bottles, bags, and pipes.

- Polypropylene (PP): Common in automotive parts and packaging.

- Polyvinyl Chloride (PVC): Rigid for pipes, flexible for hoses.

- Polystyrene (PS): For packaging and insulation.

- ABS: Strong, impact-resistant; used in electronics and toys.

- Polycarbonate (PC): Transparent, tough; used in lenses and safety gear.

- Nylon (PA): Used in gears and textiles.

- PET: Bottles, packaging.

- PMMA: Acrylic glass substitute.

- TPE: Rubber-like, for grips and seals.

Thermosetting Plastic Materials

- Epoxy: Adhesives, coatings.

- Phenolic: Electrical parts.

- Melamine Formaldehyde (MF): Kitchenware, laminates.

- Urea Formaldehyde (UF): Adhesives, boards.

- Polyurethane (PU): Insulation, foam.

- Unsaturated Polyester: Composites.

- Silicone: Seals, gaskets.

- Bakelite: Electrical insulators.

Thermoplastics and thermosetting plastics are two significant categories with distinct characteristics and uses, primarily based on their behaviour when exposed to heat. Here’s a detailed comparison of the two:

1. Thermoplastics:

Definition:

Thermoplastics are polymers that become soft and moldable upon heating and harden upon cooling. This process is reversible and can be repeated multiple times without significantly altering the chemical structure or properties of the material.

Characteristics:

- Recyclability: Thermoplastics can be melted and reshaped multiple times, making them highly recyclable. This property is advantageous for applications requiring reprocessing or reshaping.

- Heat Sensitivity: When heated, thermoplastics soften and can be easily moulded into different shapes. Upon cooling, they solidify without undergoing any chemical change.

- Bonding: The polymer chains in thermoplastics are not cross-linked; weak intermolecular forces hold them together (van der Waals forces or hydrogen bonds), allowing them to flow and be reprocessed.

- Examples: Common thermoplastics include polyethene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), polyethene terephthalate (PET), and acrylonitrile butadiene styrene (ABS).

Applications:

- Thermoplastics are widely used in applications where easy moulding and recycling are essential, such as packaging, consumer goods, automotive parts, and medical devices.

- Products include plastic bottles, toys, car dashboards, and electronic housings.

2. Thermosetting Plastics:

Definition:

Thermosetting plastics (or thermosets) are polymers that irreversibly harden upon heating. Once they are set and cured, they cannot be remelted or reshaped.

Characteristics:

- Irreversible Curing: During the initial heating process, thermosetting plastics undergo a chemical change that forms cross-links between the polymer chains. This process, called curing or cross-linking, permanently sets the material’s shape.

- Heat Resistance: Thermosetting plastics are more heat-resistant and will not melt when reheated. Instead, they will char or degrade when exposed to high temperatures beyond their stability range.

- Durability: Due to their cross-linked structure, thermosets have high structural integrity, chemical resistance, and dimensional stability, making them suitable for high-stress applications.

- Examples: Common thermosetting plastics include epoxy resin, phenolic resin, melamine, urea-formaldehyde, polyester resin, and polyurethane.

Applications:

- Thermosetting plastics require materials that maintain their shape and strength under high temperatures or stress. These include electrical insulators, adhesives, automotive components, circuit boards, and kitchenware (like melamine dishes).

- Products include electrical fittings, laminates, adhesives, and coatings.

Thermoplastics Vs Thermosetting Plastics:

| Property | Thermoplastics | Thermosetting Plastics |

|---|---|---|

| Recyclability | Recyclable; can be reshaped and remelted | Not recyclable; cannot be remelted once cured |

| Heat Behavior | Softens when heated and hardens when cooled | Cures and hardens permanently when heated |

| Bonding Structure | No cross-links; linear or branched polymer chains | Cross-linked structure, creating a rigid network |

| Mechanical Properties | Less rigid, more flexible; can be softened | More rigid, complex, and brittle; retains shape under heat |

| Applications | Widely used in packaging, consumer products, etc. | Used in high-temperature, high-stress environments |

| Examples | PE, PP, PVC, PET, ABS, PS | Epoxy, phenolic, melamine, urea-formaldehyde, polyurethane |

Examples of Thermosets and Thermoplastics in Use

Thermoset Example: Phenolic in Electrical Applications

Phenolic resin, a thermosetting plastic, has become widely used in electrical applications due to its outstanding heat resistance, electrical insulation and thermal stability properties. As such, it makes an ideal material for switchgear, circuit boards and electrical insulators; furthermore, its ability to retain structural integrity at high temperatures makes it suitable for demanding environments like switchgear housings where safety is critical. Phenolic resin’s resistance to chemicals and moisture also enhances durability – this makes it a dependable choice in industrial settings and electrical housings where safety must be paramount; beyond electrical applications, it has found use in kitchenware, automotive parts and laminate flooring, demonstrating its versatility and strength beyond.

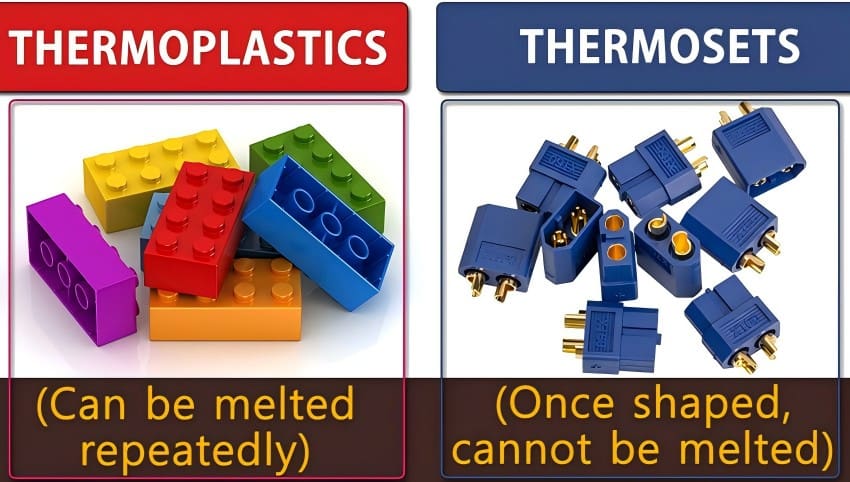

Thermoplastic Example: ABS in LEGO Bricks

ABS is a popular thermoplastic known for its strength, toughness, and versatility. It is widely used in various applications, especially in the toy industry, such as LEGO bricks. The material’s strength and dimensional stability ensure that LEGO bricks fit together precisely and retain their shape over time. ABS also resists colour fading, making it ideal for vibrant and durable toys. However, due to its opacity, it is not suitable for transparent parts. For precise components like transparent LEGO blocks, manufacturers often use polycarbonate, another thermoplastic known for its toughness and clarity. Beyond toys, ABS is also commonly used in automotive parts, consumer electronics, and protective gear due to its durability.

Understanding the specific properties and applications of thermosets and thermoplastics can help manufacturers make informed decisions about material selection, ensuring optimal performance and cost-efficiency for their products. By understanding these differences, manufacturers can select the appropriate type of plastic based on the application’s specific requirements, such as durability, flexibility, thermal resistance, and recyclability.

Thermoplastic Injection Molding from DSW

With over 25 years of experience, DSW offers excellent compression and plastic injection moulding services to original equipment manufacturers (OEMs) and organizations worldwide. Our comprehensive knowledge allows us to assist you in selecting the best thermoplastic polymer for your product, assuring optimal performance and cost efficiency. If you need a partner who can cut lead times and production costs without sacrificing quality, DSW is ready to help. Contact us today to discuss how we might help with your next project.